Structural parameters of hydrocyclones

Writer: admin Time:2020-11-10 15:37 Browse:℃

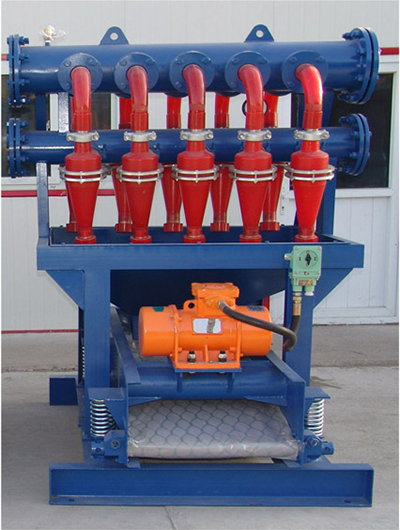

The hydrocyclone is an effective separation device that uses centrifugal force field to separate two-phase fluids. It is a non-moving separation device composed of an upper cylinder and a lower cone. The principle is that after the slurry is injected into the barrel from the feeding tube in a tangential, involute or spiral manner, the mixture of medium and particles rotates to form a centrifugal force field, and particles (or liquid phase) of different sizes and densities are generated Different trajectories, under the action of centrifugal force, medium resistance and other force fields, coarse particles and high-density particles move to the periphery and are discharged from the grit through the cone; fine particles and low-density particles (or liquid phase) It moves to the center and is discharged by the overflow pipe, and finally realizes the separation of the coarse and finely divided solid particles and fluids of different densities.

The structural parameters of the hydrocyclone:

(1) Hydrocyclone diameter: The diameter of the hydrocyclone mainly affects the production ability and the size of the separation particle size.

(2) Diameter of the feed pipe Di: The size of the feed port has a positive influence on the handling ability, the classification granularity and the classification compliance.

(3) Cone angle: increasing the cone angle, the grading particle size becomes coarser, and reducing the cone angle, the grading particle size becomes finer.

(4) Overflow pipe diameter: increase the diameter of the overflow pipe, the overflow flow will increase, the overflow granularity will become coarser, the fine particle size in the underflow will decrease, and the underflow concentration will increase.

(5) The insertion depth of the overflow pipe: The insertion depth of the overflow pipe is the length of the overflow pipe inserted into the inside of the cyclone, which refers to the distance from the bottom of the overflow pipe to the top cover of the cyclone. Reduce the insertion depth of the overflow pipe, and the grading granularity becomes finer; increase the insertion depth of the overflow pipe, and the grading granularity becomes coarser.

(6) The wall thickness of the overflow pipe: the research shows that the increase of the wall thickness of the overflow pipe can improve the separation compliance of the cyclone to a certain level, reduce its internal energy loss, and also improve the production of the hydrocyclone. Talent.

(7) The cross-sectional size of the feed port: The shape and size of the feed port have a serious impact on its production ability, separation and compliance and other industrial goals. The main function of the feed port is to change the linear movement of the liquid flow into a circular movement at the entrance of the column section. According to the cross-sectional shape, the inlet can be divided into two types: round and rectangular.

(8) Diameter of the underflow port (d): the diameter of the underflow port increases, the grading particle size becomes finer, the diameter of the underflow port decreases, and the grading particle size becomes coarser.

(9) Inner surface roughness and disassembly accuracy: The inner surface roughness and disassembly accuracy of the hydrocyclone have little effect on its production ability, separation obedience and other functional parameters. However, in production practice and research, the hydrocyclone The inner surface is lined with Xinhai wear-resistant rubber, wear-resistant and corrosion-resistant, and is relatively lubricated. It will increase the flow resistance. At the same time, the separation compliance is also added. At the same time, the flow resistance of the hydrocyclone with a rougher inner wall will be reduced. At the same time, the bottom flow increases.

(10) Feeding viscosity: the separation particle size is proportional to the square root of the feed viscosity, that is, the addition of the feed viscosity will cause the separation of the particle size to increase. The production capacity and split ratio of the hydrocyclone will also increase as the viscosity increases.

(11) Cone ratio: Cone ratio is the ratio of the diameter of the underflow port to the diameter of the overflow port. It is the main parameter of the planning cyclone, and it is also the important factor for manipulating the grading target.

Operating parameters

(1) Feeding pressure: Feeding pressure is an important parameter for cyclone work. Increasing the feed pressure can increase the slurry flow rate, and the centrifugal force on the material can increase the classification efficiency and underflow concentration. However, reducing the classification particle size by increasing the pressure has little effect, but the kinetic energy consumption is greatly increased. The overall cyclone Especially the underflow nozzle wears more serious. Low pressure (0.05~0.1MPa) operation is adopted when processing coarse materials, and high pressure (0.1~0.3MPa) operation is adopted when processing fine and muddy materials.

(2) Feeding amount: increasing the feeding amount, the grading particle size becomes coarser, and reducing the feeding amount, the grading particle size becomes finer.

(3) Concentration: When the size and pressure of the cyclone are constant, the feed concentration has an important influence on the overflow particle size and classification efficiency. When the feed concentration is high, the viscous resistance of the fluid increases, the classification particle size becomes coarser, and the classification efficiency decreases. Practice shows that when the grading particle size is 0.074mm, the feed concentration should be 10%-20%.

(4) Feeding particle size: the change of feed size will obviously affect the classification effect of the hydrocyclone. When other parameters remain unchanged, when the content of materials smaller than the classification particle size in the feed is small, the content of fine particles in the underflow is small, and the concentration is high, and the content of coarse particles in the overflow increases, and the classification efficiency of the cyclone decreases; When there are many materials close to the grading size in the material, there will be more fine-grained materials in the underflow and more coarse-grained materials in the overflow, and the classification effect will decrease.