Correct installation steps of cyclone unit

Writer: admin Time:2020-11-11 15:52 Browse:℃

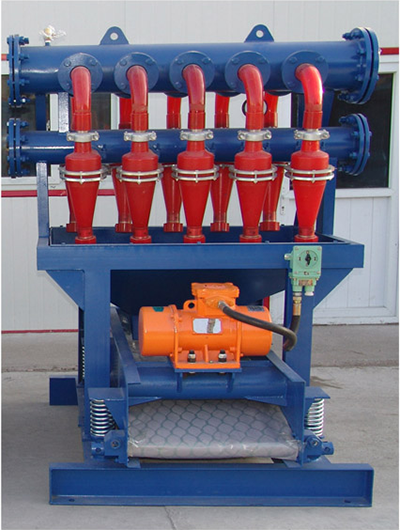

The cyclone group is a combination of cyclone equipment that requires strict installation steps before it can be used normally in the later stage. It is necessary to know that the cyclone group has a relatively strong separation capacity and high underflow solid content, so it needs to attract everyone’s attention in installation. . Today, the cyclone manufacturer will introduce to you the installation steps of the cyclone unit.

1. The erection position of the cyclone group:

When installing the cyclone group, pay attention to its starting point. The starting point of the dam should be the far point of the tailings dam, and the sand mouth of the cyclone must also be towards the far point of the dam. After working for a period of time, the underflow dam can be moved along the dam to continue stacking.

2. The problem of underflow stacking height:

When designing and installing the cyclone unit, the height of the water flow must be considered clearly. Generally speaking, it is enough not to block the underflow.

3. Mobility after installation:

The cyclone group needs to move from the starting point of the dam to the end of the dam during the dam construction process, so the requirements for the movement performance of the cyclone group are relatively high. One thing to note is to keep the same horizontal separation distance when moving.

4. The supporting feed pipe of the cyclone group:

The length of the feed pipe of the cyclone unit should reach a sufficient standard. When installing, judge according to the actual situation of the site and the equipment. In addition, the requirement of the feed pipe of the cyclone unit is that the corrosion resistance can be stronger.

1. Before starting the test run, make sure that all the connection points of the cyclone unit have been seen, and the various residues in the pipeline and the unit box are clear, so as to avoid the leakage of the machine after the start-up. Make sure to fully open the cyclone valve in operation.

2. The valve is fully opened (such as running a cyclone) or completely closed (such as a standby cyclone area), but it must never be in an open state (that is, it is not allowed to use a valve to control flow).

3. If possible, please test the car with clean water first. The feed of the cyclone can be provided by pumping or high tank. If the pump and selector throughput match, the pressure gauge will show a constant reading. To ensure that the pressure does not fluctuate, if there is obvious fluctuation, you need to check the cause. The equipment is required to work under pressure not higher than 0.3MPa.

4. When the equipment is running smoothly under normal pressure, check the leakage of the connection point and take remedial measures if necessary.

5. Check the blockage caused by the residue entering the swirling zone. The clogging of the feed port of the cyclone will reduce the overflow and underflow flow. The clogging of the underflow port of the cyclone will cause the underflow flow to decrease or even cut off, and sometimes severe vibration will occur. In case of blockage, the feed valve of the cyclone should be closed in time to clear the blockage. In order to prevent clogging, equipment to prevent coarse materials and debris (such as chip removal screen) can be added to the feed tank of the hydrocyclone group. At the same time, the feed tank should be emptied in time when the machine is stopped to avoid the precipitation concentration when driving again. Too high and cause a blocking accident.

6. When the equipment is confirmed to be running well by the clean water experiment, the input material will run.

The cyclone group usually adopts two ways of vertical installation and horizontal installation. The vertical installation method of the cyclone is suitable for working conditions with large fluctuations in feed volume and large changes in circulating load. The horizontal installation of the cyclone is an installation method where the angle between the cyclone and the horizon is 15° to 20°, which is suitable for working methods with variable circulating loads and can provide a relatively stable underflow concentration. The installation of the cyclone group usually requires the manufacturer to provide technical support and is carried out under the guidance of professional technicians. However, in the later use, it is inevitable to disassemble and assemble occasionally. How to install it quickly without professional guidance.

The correct installation of the cyclone unit determines the normal use of the later equipment, so if you have any questions about the installation introduction above, you can consult our manufacturer. Do not operate blindly without understanding, to avoid abnormal installation in the later period. A situation where the equipment does not work normally occurs.