Product Keywords: Empty section cleaner

product description

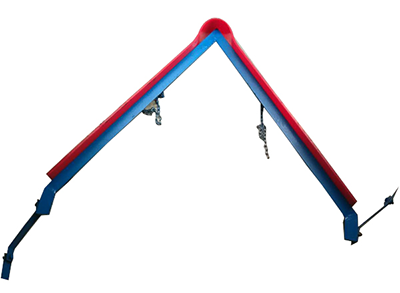

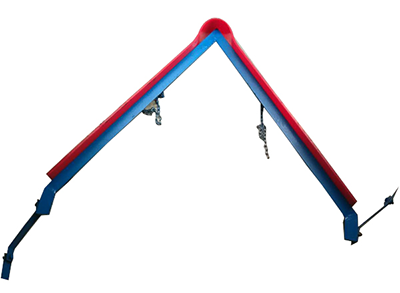

The empty section cleaner is suitable for cleaning the non-working surface of the conveyor belt. The cleaning blade is the world's top wear-resistant rubber plate imported from Germany. Its cutter head is wear-resistant, corrosion-resistant, fracture-resistant without hurting the belt. Safety High; the parallel mechanism type frame can make the cleaner close to the conveyor belt, and can automatically adjust the position of the cleaner according to the abrasion of the cleaning blade and the change of the conveyor belt position. The cleaning material is clean and effective, and the structure is simple and easy to maintain.

It is used to remove the material adhered on the non-working surface to prevent the material from entering the tail roller or the tension roller of the vertical tensioning device. It is generally welded to the middle frame in front of the tail roller and the tension roller of the vertical tensioning device and adjusted. Good chain length.

Empty section cleaner maintenance

The materials conveyed by the conveyor belt often have sticky materials, such as coal dust, mud, and powdery materials. Some of them will stick to the working surface of the conveyor belt and cannot be completely removed during unloading. They will stick to the rollers as the belt runs In the long run, it will cause the following consequences:

1. The material enters the shell of the roller, which increases the bearing wear. The material on the roller shell will damage the surface rubber of the conveyor belt and will accelerate the damage of the conveyor belt.

2. Adhesive matter enters the tail wheel and redirects to the drum. The material will stick to the surface of the drum, and the more the sticky, the more the belt will drift, increase the belt wear, and cause bad consequences.

3. The material sticks to the driving roller, which increases the friction force on the roller, which will cause damage to the surface rubber of the conveyor belt and the rubber coating of the roller.

4. The material is not removed in time, and a blanking area will be formed in the entire working channel, which will cause environmental pollution, increase the amount of cleaning labor, affect the physical and mental health of employees, and increase corporate costs.

Therefore, in order to ensure the normal operation of the belt conveyor, the attachments on the conveyor belt must be cleaned. If the cleaning device is good, the life of the idler rollers and conveyor belts can be extended.

Therefore, the cleaner must be installed in the return section to the entrance of the drum and the tail roller, that is, the empty section cleaner.

Empty section cleaner installation steps

1. Before installation, first check whether the non-working surface of the conveyor belt is damaged or reinforced with metal objects.

2. Clean off the sundries stuck on the non-working surface before installation, so that the cleaner blade can reach a stable state during operation.

3. The installation position should be selected on the non-working surface of the lower conveyor belt in front of the rear roller.

4. Install after selecting a position, adjust the position during installation so that the ground and the belt surface are in uniform contact, and there should be no contact at one end and clearance at the other end. Adjust the adjustment bolt to achieve contact balance.

5. The cleaner scraper should work properly. It must not be too large or too small. If the force is too large, the friction resistance will increase, and the large resistance will affect the service life of the scraper.