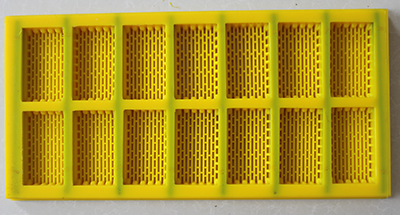

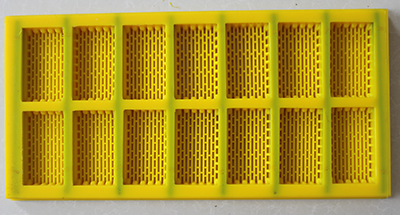

Product Keywords: WS frame sieve 300 * 600 hole 2.4

Product description

Suitable for WS sieving machine, comparable to the products of big foreign brands, and more affordable.

Application: Particularly suitable for the screening of wet and dry materials.

Size: 305mm * 305mm, 305mm * 610mm, also can be customized according to your special requirements, the maximum length can produce 3600mm skeleton screen.

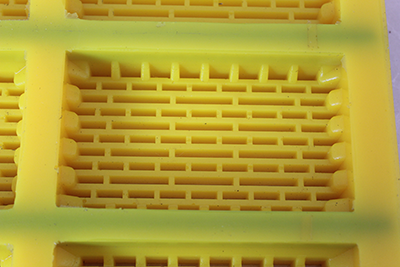

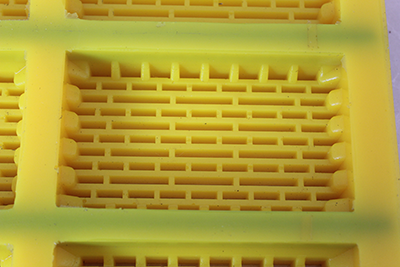

Aperture options: square holes, strip holes, round holes, continuous grooves, etc., screening size 0.1mm to 170mm.

Skeleton polyurethane screen board is the ideal choice for sieving a variety of materials, especially suitable for sieving wet or dry materials. There are also many formulations to choose from, including a highly elastic polyurethane formulation that minimizes plugging.

Main application industries: coal washing plants, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical and other enterprises.

The polyurethane sieve plate produced by Chai Shang Trading Company includes polyurethane comb sieve plate, polyurethane round (square) rod sieve plate, polyurethane inlaid frame sieve plate, polyurethane hook plate sieve and lining plate.

Has the following characteristics:

(1) The full range of sieve plates can meet the requirements of different specifications and performance of users;

(2) Good physical properties, high wear resistance, long service life, 3 to 5 times that of metal screens (nets);

(3) The noise of the elastic screen surface is low, which is more than 10db lower than that of the metal screen plate (mesh);

(4) It is not easy to plug holes and has a high sieving rate, especially the elastic sieve surface sieve, which has a good sieving effect on difficult-to-screen materials (solvents), and is an ideal substitute for ordinary sieve plates (mesh).

(5) Light weight, reasonable structure, convenient installation and removal.

Performance and characteristics

1. Good abrasion resistance and long service life. Its abrasion resistance is 3 ~ 5 times that of steel sieve plate and more than 5 times that of ordinary rubber sieve plate.

2. The maintenance workload is small, the polyurethane screen is not easy to be damaged, and the service life is long, so it can greatly reduce the maintenance volume and the loss of production and maintenance.

3. The total cost is low. Although the polyurethane sieve plate of the same specification (area) has a higher one-time investment (about 2 times) than the stainless steel sieve plate, but because the life of the polyurethane sieve plate is 3 to 5 times that of the stainless steel sieve plate, and maintenance and replacement The number of times is small, so the total cost is not high, and it is economical.

4. Good humidity resistance, can work under the condition of water as the medium, and in the case of water, oil and other media, the friction coefficient between polyurethane and materials is reduced, which is more conducive to sieving, improving screening efficiency, and avoiding wet particles At the same time, the friction coefficient is reduced, the wear is reduced, and the service life is increased.

5. Corrosion resistance, non-flammable, non-toxic and tasteless.

6. Due to the reasonable design of the sieve holes and the unique manufacturing process of the sieve plate, the particles of the limit size will not block the sieve holes.

7. Good vibration absorbing performance, strong noise elimination ability, can reduce noise, and make the objects on the sieve difficult to break during the vibration process.

8. Due to the characteristics of the secondary vibration of polyurethane, the polyurethane screen has a self-cleaning effect, so the screening efficiency is high.

9. Energy saving and consumption reduction. The proportion of polyurethane is small and much lighter than steel sieve of the same size, which reduces the load on the screener, saves power consumption, and extends the life of the screener.

Excellent abrasion resistance and long service life: 8 to 10 times longer than ordinary metal wire mesh, 3 times longer than stainless steel wire mesh, and 3.9 times longer than natural rubber. It is currently the world's best wear resistance. Screen surface material.

The maintenance workload is small. The polyurethane frame sieve is suitable for work under heavy load, and it will hardly be damaged under normal operation. Due to less maintenance and downtime, a lot of time and energy is saved, which can greatly improve the efficiency of the screening machine and reduce the operating costs of the station.

Our polyurethane and rubber screens reduce noise levels by up to 9 decibels. This is a 50% reduction in noise perceived by the human ear. This means that staff can work nearby for longer without harming their hearing.

A variety of fixing methods are available, including pin fixing, bolt fixing, clip type and bead connection. Whether you need the most stable installation, easy installation and removal, the best versatility or a combination of all of them, we can provide a mounting system to meet your needs.

Modular Screen Panel is a new type of product developed in recent years to replace metal sieve plate on sieving machines such as mine beneficiation, classification and dewatering. It is mainly used in the classification, screening and dewatering of coal, iron, copper, gold and other ore. It is one of the necessary accessories for vibrating screen.

Due to the harsh conditions of the sieve plate, not only the wear resistance, corrosion resistance and aging resistance are required, but also the precise size of the sieve holes and slits must be maintained during use.In the past, the sieve plate was mainly made of stainless steel, but due to the wear resistance of metal , Elasticity, corrosion resistance is poor, and the noise is high, the processing cost is high, and the life is short. In most cases, it is being replaced by a polyurethane screen.