Steps of using high frequency dehydration screen

Writer: admin Time:2020-04-22 10:56 Browse:℃

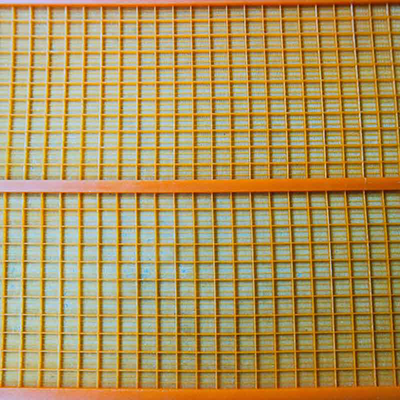

The dewatering sieve is widely used in ore dressing, sand washing, coal preparation plants and other industries. The high-frequency dewatering sieve has a reasonable structure and special novelty. It uses a vibration motor as an excitation source, and the material is thrown to achieve the purpose of screening treatment There are also more and more customers who purchase dehydration screens. For these customers, of course, they hope that the life of dehydration screens will become longer and longer, so as to bring more economic benefits to themselves. What are the steps for using the high-frequency dehydration screen and under what conditions will the high-frequency dehydration screen work better? Let's learn with polyurethane screen manufacturers together:

(1) Bearing. The bearing is an important part of the dewatering screen parts. Wet bearings are unavoidable in the dehydration process. The bearing will rust or corrode after a long time. Therefore, the maintenance of the bearing is usually very important. The bearing can be cleaned after cleaning. The bearing should also be coated with a layer of anti-rust oil or anti-rust grease.

(2) Quality of parts. The quality of each part is also very important to the service life of the dewatering screen. The quality of the parts determines the quality of the whole machine, so we must choose good quality parts. The bearings of our heavy industry are all Xinxiang bearings. The company's purchase volume is large, so it has a year-round cooperative relationship with Xinxiang Bearing Factory, and the quality is greatly guaranteed. The bearings used by our company have undergone various tests and can withstand strong acid corrosion. If the parts are damaged, we There is after-sale home repair.

(3) Vibration motor. When the dehydration screen is working, due to the large amplitude, some water will splash on the vibration motor, so the purchase of the vibration motor is also very important. The poor selection of the vibration motor directly affects the dehydration effect. Our company uses a new type of vibration motor , Perfectly solved this problem.

Advantages of high-frequency dehydration sieve:

(1) Good sealing effect and high strength;

(2) Abrasion-resistant natural rubber is attached to the position of contact with the material, which is corrosion-resistant and wear-resistant;

(3) Wear-resistant rubber shock absorber can make the screen run more stable and lasting;

(4) The product is integrally connected to the screen box with good rigidity and no thermal stress;

(5) The side body shield of the high-frequency dewatering screen is bonded with wear-resistant rubber to ensure that the dewatering screen does not receive wear and cause deformation and cracking, and reduces the pollution of materials;

(6) Post-set low-concentration slurry overflow pipe to speed up dehydration;

(7) The low water content of the discharged material effectively guarantees the quality;

Under what conditions will the high-frequency dehydration sieve work better?

1. The use environment should be free of conductive dust, flammable, explosive and corrosive gases.

2. The altitude does not exceed 1000 meters. If it exceeds 1000 meters but does not exceed 4000 meters, the temperature rise limit should be reduced by 0.5 ° C for every 100 meters of increase.

3. Vibration acceleration does not exceed 20g (g: 9.8m / s gravity acceleration).

4. The ambient temperature does not exceed 40 ℃ (if it exceeds 40 ℃, the power should be reduced).

5. Power supply: three-phase 380V, frequency 50Hz.

6. Working mode: SI (continuous).

7. The stator winding temperature rise value (resistance method) does not exceed 80K.

8. The allowable temperature of the bearing (thermometer method) should not exceed 95 ℃.

9. The working current of the host does not exceed the data on the motor nameplate, otherwise the excitation force is reduced.

The structure of the high-frequency screen is novel. The vibration motor is used as the excitation source to make the high-frequency dewatering screen more efficient. The high-frequency dewatering screen is small in size and low in noise. It will not cause any pollution to the environment. In addition, in the high-frequency dewatering sieve, the service life of the screen composed of high-strength polyurethane high-frequency screen is longer.