Common abnormalities of hydrocyclones

Writer: admin Time:2020-08-17 11:11 Browse:℃

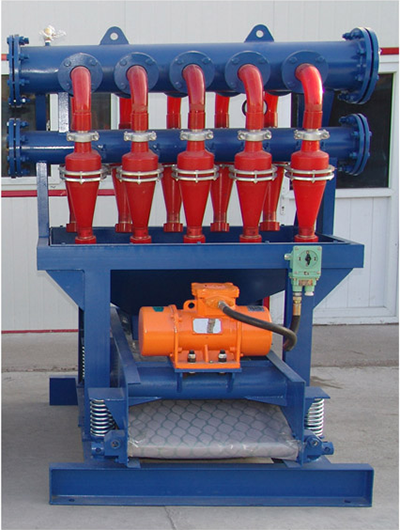

Overflow of hydraulic grading cyclone (the normal feeding pressure of the hydraulic grading cyclone should be between 0.10-0.15MPa, and the maximum cannot exceed 0.30MPa. The feeding pressure can be controlled by the variable frequency of the coal slurry pump. The grading particle size of the hydraulic grading cyclone : 100~200μm, namely 0.1-0.2mm).

1. Feeding pressure fluctuations: Feeding pressure should be stable at the pressure required for production and no major fluctuations should occur. Fluctuations in feed pressure will damage the performance of the equipment and affect the classification effect of the cyclone. Pressure fluctuations are usually caused by insufficient pump feed due to the drop in the pump tank liquid level and air traction or the blockage of debris entering the pump. The pressure drop after a long period of operation is caused by pump wear.

Adjustment: ① If the pressure fluctuation caused by the drop of the pump tank liquid level, it can be adjusted by increasing the liquid level or closing one or two cyclones or reducing the pump speed. ②If the pressure fluctuation is caused by the blockage or wear of the pump, the pump needs to be repaired.

2. Blockage: Check whether the overflow and underflow discharge of all cyclones in operation are unblocked. If the flow rate of the overflow and underflow of the cyclone is reduced or the underflow is cut off, it indicates that the cyclone is blocked.

Adjustment: ①If the overflow and underflow flow are both reduced, it may be that the feed port of the cyclone is blocked. At this time, close the feed valve of the blocked cyclone, remove it, and remove the blockage; ②If the underflow flow is reduced If the flow is small or cut off, the underflow port is blocked. At this time, the flange can be removed to remove the debris in the underflow port.

3. Analysis of underflow parameters: often observe the underflow discharge status of the cyclone, and regularly check the underflow concentration and fineness. The fluctuation of the underflow concentration or the "underflow pinch" should be adjusted in time. Under normal working conditions of the cyclone, the underflow discharge should be "umbrella". If the underflow concentration is too large, the underflow will be discharged in a "columnar" or intermittently "lumpy" shape.

Adjustment: ① The high underflow concentration may be caused by the feed slurry concentration or the underflow opening is too small. You can add an appropriate amount of water to the feed first. If the underflow concentration is still large, you need to replace a larger underflow port. ② If the underflow is discharged in an "umbrella shape", but the underflow concentration is lower than the production required concentration, it may be caused by the low feed concentration. At this time, the feed concentration should be increased. ③The cause of the "fine underflow clamp" may be that the underflow aperture is too large, the overflow pipe diameter is too small, and the pressure is too high or too low. The pressure can be adjusted first, and then replaced with a smaller underflow port, and gradually debug to normal production state.

4. Analysis of overflow parameters: regular detection of overflow concentration and fineness. The increase in overflow concentration or "overflow running rough" may be related to the increase in feed concentration and the blockage of the underflow port. Adjustment: It is found that "overflow running thick" can first detect whether the underflow port is blocked, and then detect the feed concentration, and adjust according to the specific situation.

5. Equipment maintenance:

The wear of each part of the cyclone should be checked frequently. If the thickness of any part is reduced by 50%, it must be replaced.

The most easily worn part of the cyclone is the underflow orifice. If the underflow clamp is found to be thin, check whether the underflow orifice is worn or not, and replace the underflow orifice.

6. If water leakage is found in the upper part of the slurry valve before the cyclone feeds, the four hexagon socket bolts at the upper end of the valve body can be tightened until there is no water leakage; if it is tightened too much, it will be difficult to lift the valve gate.

1. Before using the hydrocyclone, be sure to clear the oversized ore particles, slag, grass roots and other debris in the equipment before feeding the slurry into the hydrocyclone. When feeding the slurry again, it is necessary to maintain a stable and constant pressure feeding at the same time. This is to achieve a better classification effect.

2. In the actual production process, the sand pump is generally used to feed the mine directly. Due to the influence of the operating state of the hand sand pump, the pressure of the mine will fluctuate. In order to solve this problem, a frequency converter is generally installed, and at any time according to the changes of the situation. Adjust the number of revolutions of the sand pump to achieve the purpose of stabilizing the feed pressure. If the mine plant can install a constant pressure box under the allowable conditions of the terrain and height to achieve constant pressure to the mine.

3. In addition, the grading effect is also affected by the ore concentration and particle size. Therefore, the ore concentration and particle size should be kept as stable as possible during the production process, and the fluctuation range should not be too large.

4. If the feed concentration of the cyclone reaches or exceeds 70%, it will seriously affect the normal operation of the hydrocyclone, resulting in failure to classify, so special attention should be paid to the change of the feed concentration during production.

During the whole production process, the fineness of the overflow of the cyclone should be carefully controlled, and the shape of the dust and sand discharged by the dust and sand nozzle. Umbrella and rope shapes are more ideal. If the shape of the discharged dust and sand is like a sausage, pay attention to prevent The clogging of the sand outlet occurred.

The wear of the hydrocyclone is one of the more important usage indicators. The sand discharge nozzle and the lower cone connected to it are worn out. In order to prevent wear, it is recommended that the cyclone body be lined and equipped with replaceable parts made of wear-resistant materials, which can be replaced at any time. Commonly used wear-resistant materials are rubber, polyurethane, silicon carbide and so on.