Advantages of polyurethane high frequency screen

Writer: admin Time:2020-08-27 15:16 Browse:℃

What are the advantages of high-frequency screens and installation methods? The high-frequency screen manufacturers will give you a brief introduction. The installation of high-frequency screens generally requires 2-3 people, a special caliper and a special buckle. First of all, for the installation of the column, the column is pre-embedded 40 cm. If you want to ensure the firmness of the column, it is recommended to use cement.

high frequency screen installation

1. The buckle must be stuck on the cross intersection of the barbed wire and stuck firmly with a caliper. This is stronger.

2. Install an extra column at the corner of installation and try to avoid right-angle turning.

3. It is inevitable that there will be small local abrasion and exposed inner wire during transportation. It is recommended to repair it with self-painting after installation to ensure a longer service life of the product.

Advantages of high frequency screen

High frequency screen material: stainless steel wire 201 high frequency screen composite screen, 304 high frequency screen composite screen, 316 high frequency screen composite screen, 316L high frequency screen composite screen.

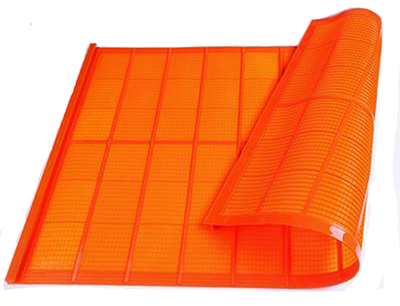

High-frequency screen products are made by stacking standard stainless steel wire meshes in a fixed structure and processing them through processes such as vulcanization, cutting pieces, folding hooks, etc., into a stainless steel wire mesh product.

High frequency screen product characteristics: wear resistance, corrosion resistance, temperature resistance, high opening rate, long service life, high strength, rigidity and load-bearing capacity, and can be made into rigid screening and filtering devices of various shapes.

High-frequency screen product use: widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries. Screen liquid, powder and other materials. Petroleum, chemical industry, metallurgy, mining, pharmaceutical purification, drilling fluid purification, etc.

High-frequency screen products: It is a new type of filter material with high mechanical strength and overall rigid structure that is made of multi-layer metal braided wires through special lamination and vacuum sintering processes. The meshes of each layer of wire mesh are interlaced to form a uniform and ideal filtering structure, which not only overcomes the low strength, poor rigidity, and unstable mesh shape of ordinary metal wire mesh, but also can control the pore size of the material. Permeability and strength characteristics are reasonably matched and designed, so that it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and processability. The overall performance is significantly better than that of sintered metal powder, ceramics, Fiber, filter cloth, filter paper and other types of filter materials.

In order to meet the needs of coal slime recovery and dewatering and classification of fine-grained materials, high frequency vibrating dewatering screen adopts the mechanical characteristics of high frequency and high vibration intensity to achieve the purpose of large processing capacity, good dewatering effect and strong adaptability.