High frequency screen operating instructions

Writer: admin Time:2020-09-10 14:36 Browse:℃

High frequency screens are widely used in many construction sites, but many people do not know how to operate, so the following high frequency screen manufacturers have compiled the operating instructions of high frequency screens for your reference.

Polyurethane high-frequency screen has the advantages of high screening efficiency, large processing capacity, compact and reasonable structure, small footprint, and low power consumption. The screen frame is supported by a rubber spring suspension, with low noise, low power consumption, and small equipment dynamic load, so there is no special requirement for the installation foundation. Forcing the slurry to be distributed to the mine can spread the slurry evenly on the screen surface, reduce the slurry flow rate on the screen surface, and extend the life of the screen. The dual vibrator configuration, linear vibration and patented technology of re-pulping, the screening material flow area is long, the transmission speed is fast, and it has a greater screening capacity and screening effect. The surface of the equipment is treated with anti-corrosion and wear-resistant spray glue, which effectively extends the life of the equipment.

Galvanized high-frequency screens are roughly divided into two types in shape, one is called whole-woven galvanized high-frequency screens, and the other is called step-flower galvanized high-frequency screens. What are the similarities and differences between these two shapes of galvanized high frequency screens? From several important aspects such as raw materials, usage and weaving process, the whole woven crimped net and the stepped crimped net can be substitutes for each other. The two are not essentially different. If you have to distinguish one or two points, the first thing is in terms of usefulness. The mesh surface made of the whole woven galvanized high-frequency screen is softer, but the wear resistance is better than that of the high-frequency galvanized high-frequency screen of the step flower.

According to this difference, the whole woven galvanized high-frequency screen and the stepped galvanized high-frequency screen should be used in different occasions according to the needs. The whole woven crimped net means that there is no wave-shaped zigzag in the center of a single mesh, and the stepped crimped net means that there are one or more wave-shaped zigzags in a single mesh. Whole-woven galvanized high-frequency screens are mostly used for small-sized crimped wire meshes with large holes, and stepped galvanized high-frequency screens are mostly used for large-sized crimped wire meshes with small holes. The center state can be used for whole weaving or order flower. In most cases, there is no difference between the whole woven galvanized high frequency screen and the step galvanized high frequency screen.

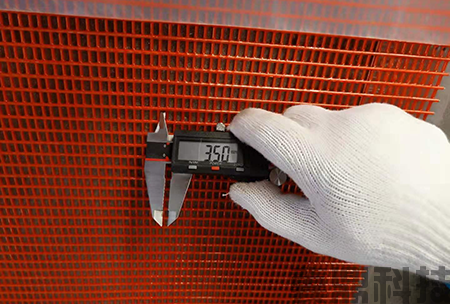

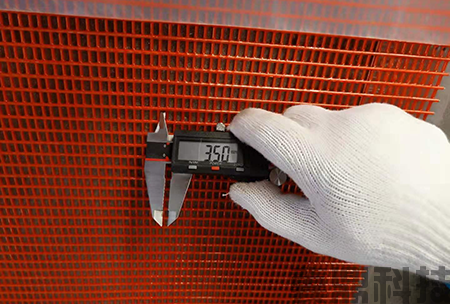

Galvanized high-frequency screen mesh specifications: wire diameter 70-600 wire, mesh 1-24 mesh. customizable. It is a composite wire with a copper layer wrapped around the steel wire. It uses the skin effect of low-voltage and high-frequency signals to walk along the surface in the high-frequency region. Therefore, only the thickness of the copper layer needs to reach a certain range, and the signal in a certain frequency range can be Be assured of notification. Copper plays a role in conducting weak electrical signals, while steel wire plays a supporting role. Bright butt welding needs to be blocked due to sparks and splashes. With the development of industries such as aerospace, electronics, steel mesh structures, automobiles, and household appliances, resistance welding has attracted more and more attention from the society. At the same time, there is a higher demand for the quality of resistance welding.

Fortunately, the development of China's microelectronics technology and the development of high-power thyristors and rectifiers have provided conditions for the improvement of resistance welding skills. At present, China has produced secondary rectifier welding machines with excellent performance. A control box made of a structural computer with integrated components and a micro-meter steel wire mesh has been used for the matching of new welding machines and the transformation of old welding machines. Constant current, dynamic resistance, thermal expansion and other closed-loop monitoring techniques have begun to be promoted and applied in production.

There are indeed many types of high-frequency screens. As long as you understand these types, you can perform better operations accordingly to ensure work efficiency. For more questions about high-frequency screens, please refer to other content on this site, or call for detailed inquiries.