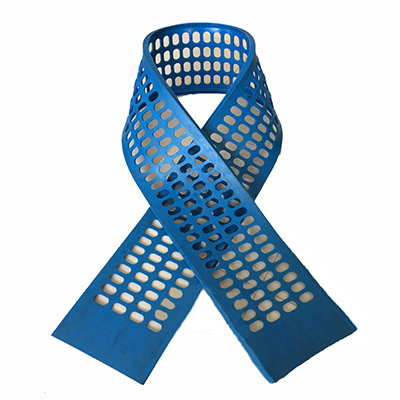

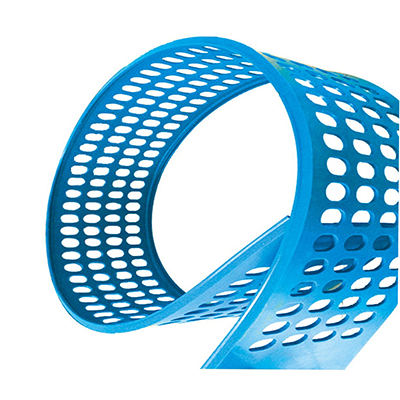

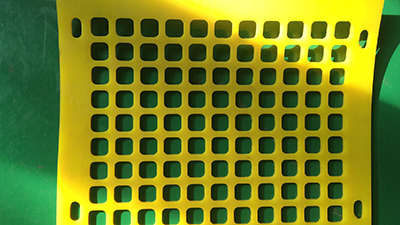

Product Keywords: Polyurethane Relaxation Screen

Product description

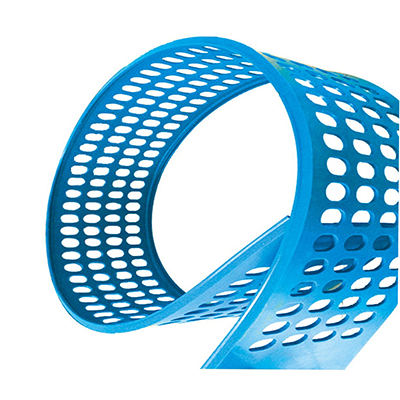

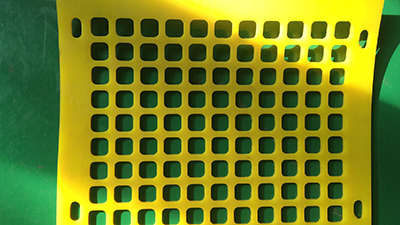

Polyurethane relaxation sieve generally adopts square or oblong sieve holes, and is made of pure imported polyurethane raw materials. Equipment for screening difficult, sievable materials such as fine, sticky, wet (such as medium- and fine-grained classification of high-viscosity raw coal and coke with high viscosity), especially when the processed materials are liable to block the screen At the same time, the relaxation screen can achieve a very high screening efficiency with a relatively small screen layout and ensure that the screen is not blocked.

Working principle of slack relaxation sieve

The relaxation screen is a dual-mass vibration system. It adopts a polyurethane rubber screen surface. Any two adjacent beams supporting the screen surface belong to two vibrating masses, one of which is a screen box and the other is a matching body. weight. During work, the screen is alternately tightened and loosened, so that the material has a forward bounce motion, which can prevent the material from sticking to the screen and blocking the screen hole. When the two masses vibrate in two phases, any two adjacent beams are sometimes close to each other, sometimes away from each other, and the elastic screen surface is sometimes loosened and sometimes tensioned. Make relative movements. This relaxation motion not only continuously deforms the screen holes, but also greatly increases the vibration intensity of the screen surface, thereby effectively overcoming the phenomenon of screen hole blockage and significantly improving the processing capacity of the screen machine. However, since the vibration intensity of the screen box is not large, the mechanical strength is easy to ensure, but the vibration intensity of the screen surface is large and repeatedly deformed, so the life of the screen surface is low.

Screen repair steps for relaxation screen equipment:

1. After the screen frame of the relaxation screen equipment is assembled into the screen box as required, remember to extend the cut out 50-70mm screen into the corresponding discharge port to avoid mixing.

2. When cutting, the width of the screen of the relaxation sieve equipment must be consistent with the grid frame. The length of the screen must be 50 ~ 70mm longer than that of the dolomite relaxation screen equipment.

3. When the screen is installed, it must be tightened, because the tension of the screen is an important factor affecting the screening efficiency of the relaxation screen equipment;

4. When installing a clear net bouncing ball, we must pay attention to the screening difficulty and the number of meshes of the material, and cannot be installed blindly;

5. If the specific gravity of the material is large or the number of sieve meshes to be installed in the relaxation sieve equipment is high, a suitable supporting net should be added under the sieve. The purpose is to support and reduce the amount of material on the sieve. Pressure to extend its service life;

6. When installing the pressure plate of the relaxation sieve equipment, we must pay attention to its flatness, and line it with a highly elastic sponge sealing belt to evenly lock it, because this is not only the key to prevent the occurrence of mixing level, but also affects the use of the vibrating screen Important factors of life

7. After installation, use a little material to test the screen cloth and sieving condition. If the material is conveyed evenly, and the classification is accurate, and there is no mixing, it means that it can be put into use; otherwise, if deviation or For unevenness such as stacking, the flatness and uniformity of the screen surface of the relaxation screen equipment or the angle of the eccentric hammer of the vibration motor should be adjusted; if mixing phenomenon occurs, the seal and pressure of the screen of the relaxation screen equipment should be checked tight.

1. Segmented screening, the screen machine does not vibrate as a whole. The screen vibration dolomite relaxation screen is different from other vibrating screens. It does not participate in vibration as a whole. The side plate, top cover and base of the screen machine are fixed parts. Only the screen and shaker assembly are involved in the vibration.

2, self-cleaning sieve surface. The relaxation screen equipment adopts a variety of anti-blocking screen technology, whether it is ordinary wet sticky raw coal, wet sticky lignite, or working conditions such as adding coal slime, adding vermiculite, and washing coal in raw coal. Relaxation sieving equipment can not block holes, maintain high screening efficiency,

3. Closed structure. The relaxation sieve equipment is applied in high dust industrial and mining conditions, and generally made into a closed structure, so that the dust cannot be leaked out, thereby responding to environmental protection requirements.

4. The larger amplitude and smaller dynamic load relaxation sieve equipment adopts the process characteristics of the screen body not vibrating and the screen vibration, so the dynamic stress of the screen machine can be reduced to a low level, so the amplitude can be greatly increased, but the dynamic load is Can be greatly reduced.

5. Smaller power Due to the fewer moving parts of the relaxation sieve device and the lower vibration mass, its power can be reduced to a low level. Compared with the traditional sieve machine, it can reduce the power by more than double.

6. The unique PLC control system relaxation sieve equipment generally uses 1 to 6 motors to drive, each motor starts at an interval of 6 to 8 seconds, starts in the forward direction, and stops in the reverse direction to achieve the purpose of empty car startup. No material is stored on the sieve to facilitate observation and maintenance. So the relaxation screen equipment adopts PLC to control the whole equipment start, stop, manual, remote control and other series of actions.

7.Easy to maintain The relaxation sieve equipment has few components to vibrate. Only the screen and shaker assembly participate in the vibration, so we make it into a modular and standardized component for quick replacement as a whole and ground maintenance, which greatly shortens it. Online repair time to earn time for safe production.

Application

Polyurethane relaxation screen is widely used in coal, electric power, coal chemical industry, metallurgy, building materials and other industries. It is used to classify and screen fine ore materials, and to improve the economic efficiency in the process of coal washing industry.

Use advantage

1.Since the sieve surface undergoes relaxation motion, it can transmit the acceleration of 50G to the material, so it can screen the difficult-to-screen material, and the screen hole is not easy to block.

2. The advantages of banana sieve and relaxation sieve are organically combined. The material at the feeding end is fast, the material layer is thin, a large amount of material passes through the screen, and the processing capacity is high. The inclination angle of the sieve at the discharge end is low, and the material speed is slow, which can thoroughly penetrate the remaining sieving material to achieve a very high screening efficiency.

3. Linear motion box shaker has high reliability and easy maintenance.

4. The polyurethane sieve plate of the relaxation sieve is specially designed by Tongtai Machinery Co., Ltd. to withstand a vibration strength of 50g and 800 times per minute of flexure. The sieve plate has a long service life and the sieve machine is located on a hollow rubber spring. Small, and rubber springs have a long life. The load on the screen and the supporting structure is much smaller than that of the conventional relaxation screen (although the relaxation screen can produce a vibration strength of 50g, which is much larger than the traditional screen's 5g).

5. The "U" design of the side of the screening machine is used to form a seal, and the side plates have no wear, and it prevents the sieve from entering under the sieve. The sieve plate is fixed with wedge-shaped rubber strips without any bolts. The extension has fewer rotating parts, high operation reliability, less daily maintenance workload, high utilization rate, and adjustable screen sieve technology parameters:

Instructions for use

1. Relaxation screen design, compact and easy to assemble, one person can operate the screen.

2. Compared with other types of screening equipment, it has a larger screening area and high efficiency processing capacity.

3. Unique screen structure design, easy and fast screen replacement (only 3 to 5 minutes). In addition, this design allows the use of various screens (nylon, special dragon, PP screen).

4. The mother net fully supports the fine net, so the fine net can have a long life, and the use of fine mesh consumables can be reduced. The long production process can reduce many costs.

Regular maintenance

Regularly check the coarse mesh, fine mesh and springs for fatigue and damage, and if any part of the fuselage is damaged due to vibration, the parts that need to be lubricated must be lubricated. Vibration: With the model, the specifications of the screen surface, the number of layers on the screen, the size of the screen, the size of the feed, the amount of processing, the power of the motor, the vibration frequency, and the double amplitude, these data can give people who search for a vibrating screen a deeper understanding.