Long service life of polyurethane screen

Writer: admin Time:2020-04-27 13:58 Browse:℃

Vibrating screen is an indispensable main equipment in beneficiation and grading operations. There are many specifications and models. In order to meet different grading and dewatering purposes, the screen structure assembled has a variety of structural forms, sizes, screen size and distribution. The net is one of them. It has the characteristics of light weight, high screening efficiency, not easy to plug holes, wear resistance, impact resistance, long life, etc., but unreasonable selection, use and processing technology will have a great impact on its life, resulting in the operation of the vibrating screen Increased costs. Why does the polyurethane screen plate have a longer service life than ordinary screen plates? We understand with polyurethane screen manufacturers:

First, when argon arc welding, can form a molten pool of more than 1000 degrees, the welding force is metallurgical bonding force, the bonding force of polyurethane screen resistance welding is bonding bonding force.

Secondly, in the continuous argon gas welding, the argon arc welding is that the welding joint cannot be in contact with the oxygen in the air, which effectively prevents the oxidation of the welding material and has a longer life than the ordinary sieve plate? There is no protective measure for the resistance welding of the polyurethane sieve plate. An oxide film will be formed between the welding points of the sieve bar and the support bar, which will affect the welding effect and the welding is not firm.

Third, resistance welding uses water cooling in the welding process, the welding spot suddenly cools, the welding part of the bar becomes hard, brittle and brittle, greatly reducing the service life; the argon arc welding spot is naturally cooled and will not harden and brittle.

Fourth, argon arc welding adopts flat welding. The surface of the sieve plate is smooth like a mirror, without wavy protrusions, the wear is even during use but the resistance welding is limited by the process, the surface of the sieve plate is not smooth, and has wavy protrusions, which becomes a weak link, which is easy to be worn by the medium during use

What is the detailed classification of polyurethane sieve

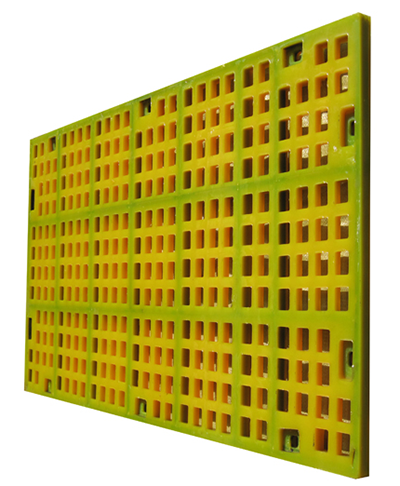

First of all, according to the production process, it can be divided into: straight groove screen plate and punching screen plate.

Second, the linear slit screen is divided into: full stainless steel screen, polyurethane edge screen and full polyurethane screen.

The lower punching screen plate is divided into: stainless steel punching screen plate, manganese steel punching screen plate and iron plate punching screen plate.

Fourth, the linear slit screen is a rectangular hole with a narrow and wide cross section.

Fifth, the sieve plate is round hole, square hole, special-shaped hole, and the upper and lower sections are the same.

Polyurethane screen has excellent physical functions, both toughness and rigidity, to ensure the stability of the screen gap during the use of the screen, the maximum limit to ensure the stability of the particle size under the screen, and it is not easy to plug the hole. The use of leading precision mold technology guarantees a high opening rate and the maximum limit to ensure a high screening efficiency.

Polyurethane screen has a long service life and a large carrying capacity. Because the polyurethane elastic screen uses steel wire as the skeleton material, and the polyurethane itself has a very high elastic modulus, high strength to absorb impact and high wear resistance, it has high tensile strength, and its load-bearing capacity is a rubber screen More than 2.5 times. Its service life is 8-10 times higher than ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is currently the world's best wear-resistant screen surface material. The production material of the polyurethane screen is a polymer organic elastomer, which has excellent resistance to wear of the polyurethane screen, flexural resistance, and large bearing capacity.