How to choose high frequency screen

Writer: admin Time:2020-04-27 15:01 Browse:℃

Screening is the process of separating particles by size and fine screening

Usually refers to the interval between 10 mm to 38 microns (400 mesh). In fine wet screening, the fine screening surface is the main key of the stack screening screening machine, which will directly affect the separation efficiency and screening performance. We design and manufacture fine mesh, wear-resistant polyurethane screen plates for fine screening. Our polyurethane screen has high opening area and anti-blindness, and has unmatched performance of traditional woven wire mesh.

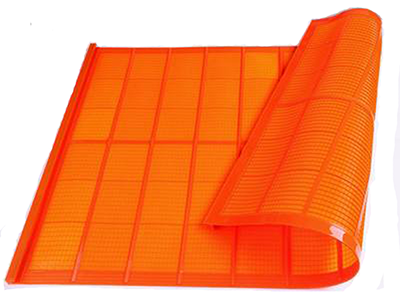

High frequency screen specifications

Screen size: 1040x700mm

Accuracy of hole opening up to 0.075

Normal service life: 6-12 months

Material: polyurethane material

For high-frequency vibrating screen-stacking screening machine

High opening area 32%-42%

Integrated fiber-reinforced technology can prevent it from breaking, thus improving the tensile strength and service life of the screen

Anti-blind tapered hole design improves screening performance and efficiency

1. Good wear resistance and long service life. Its wear resistance is 3 to 5 times that of steel sieve, and more than 5 times that of ordinary rubber sieve.

2. The maintenance is convenient, the polyurethane net is not easy to damage, and the service life is long, which can greatly reduce the amount of maintenance and the loss of downtime maintenance.

3. The total cost is low. Although the one-time investment of polyurethane mesh of the same specification (area) is higher than the one-time investment of stainless steel screen (about 2 times), the total cost is not high, because the service life of polyurethane mesh is 3? Times, and less maintenance and replacement time, so it is very economical.

4. Good moisture resistance makes it work under water as medium. In the case of water, oil and other media, the coefficient of friction between the polyurethane and the material is reduced, which is more conducive to screening, improves screening efficiency, and avoids the adhesion of wet particles. In addition, due to the reduction in friction coefficient and wear, the service life is increased.

5. Anti-corrosion, non-flammable, non-toxic and tasteless.

6. Reasonably designed screen holes and unique screen plate manufacturing process will not cause particles with limited size to block the screen holes.

7. Good shock absorption performance and strong noise reduction ability can reduce noise, and can also make the material on the screen not easy to break during vibration.

8, due to the characteristics of the secondary vibration of polyurethane, the polyurethane screen can be cleaned by itself, and the screening efficiency is high.

9. Energy saving and cost reduction. Polyurethane has a smaller specific gravity and is much lighter than screens of the same size, thereby reducing the load on the screening machine, saving electrical energy, and extending the life of the screening machine.