The difference between polyurethane screen and ordinary meta

Writer: admin Time:2020-05-06 11:06 Browse:℃

What is the difference between polyurethane screens and ordinary metal screens, why polyurethane screens are better than ordinary metal screens, polyurethane screen manufacturers come to explain to you: the wear resistance of polyurethane screens is higher than that of steel plates Times, the wear resistance of the general rubber sieve plate is increased by 5 times. The maintenance workload is small, the polyurethane sieve plate is not easy to damage, and the service life is long, which can greatly reduce the maintenance amount and production maintenance loss. Although polyurethane screen plates of the same standard (area) are higher than stainless steel screen plates (about 2 times) at a time, the total cost is lower.

However, because the polyurethane sieve plate is 3-5 times longer than the stainless steel sieve plate, the number of maintenance and replacement is less, the total cost is not high, and it is economical. The moisture-proof performance is good, it can be operated under the condition of water as the medium, and under the condition of water, oil and other media, the friction coefficient of the polyurethane and the material is reduced, which is more conducive to the screen.

Compared with ordinary metal screen, polyurethane screen

1. Its long service life and large carrying capacity. Because the polyurethane elastic screen uses steel wire as the skeleton material, and the polyurethane itself has a very high elastic modulus, high strength to absorb impact and high wear resistance, it has high tensile strength, and its load-bearing capacity is a rubber screen More than 2.5 times. Its service life is 8-10 times higher than ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is currently the world's best wear-resistant screen surface material. The production material of the polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flex resistance and large load-bearing capacity. The raw materials of the polyurethane screen have been specially treated to ensure that it will never delaminate under the effect of long-term alternating load.

2. High screening efficiency. The self-cleaning performance of the screen surface does not block the holes and the screening efficiency is high. Due to the strong water permeability of polyurethane and the large cone angle (140 °), it can effectively prevent the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine particles. The polyurethane screen of our factory adopts imported raw materials, its elastomer and its own good relaxation performance, and it can effectively avoid the phenomenon of blocking holes under dynamic conditions.

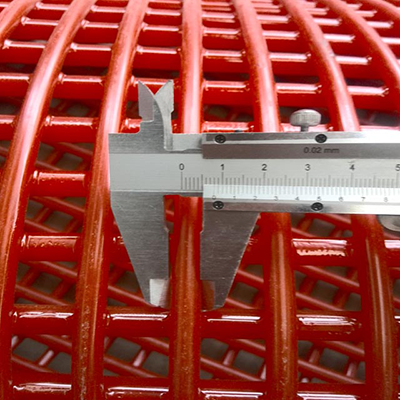

3. High screening accuracy. The production process of the polyurethane screen adopts the mold casting molding process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can well meet the requirements of the user.

4. Wide range of application, stronger professional applicability, suitable for any type of vibrating screen machine and can be made by measuring machine. Polyurethane mesh is professionally used in hydropower stations, building materials and other metal beneficiation mining. The sieving of various materials within the range of 0.1mm-170mm, regardless of the dry sieve and wet sieve, does not affect the screening efficiency. For the dewatering and deintercalation sieve in the range of 0.5m-3mm, the superiority of the polyurethane sieve surface is more fully shown. The product is resistant to water, corrosion, and aging, and is easy to replace and maintain. Polyurethane has a low density (1.32kg / m 3) and is lighter than the metal screen surface, which can reduce the production unit consumption, so it can adapt to the large-scale development requirements of the screen machine.

5. Moreover, it is easy to install and easy to replace and overhaul. This product is suitable for any type of sieving machine. It is light in weight. It is a field installation or replacement overhaul, which greatly reduces the workload.

Improve the screening ability, prevent the adhesion of wet particles, at the same time reduce the friction coefficient, reduce wear and improve service life. Corrosion-resistant, non-flammable, non-toxic and tasteless. Since the screen planning is reasonable and the manufacturing process of the screen plate is the same, the particles of the limit size will not block the screen. During the vibration process, the vibration absorption performance is good, the sound suppression ability is strong, the noise is reduced, and the material on the screen is not easily broken.

Due to the characteristics of the secondary oscillation of polyurethane, the polyurethane sieve plate has a self-treatment effect, so the screening power is high. Energy saving and consumption reduction, the specific gravity of polyurethane is much lighter than that of the same size and thin steel screen, thus reducing the load of the screening machine, saving electricity consumption, and extending the service life of the screening machine.