Why choose polyurethane screen

Writer: admin Time:2020-05-07 11:43 Browse:℃

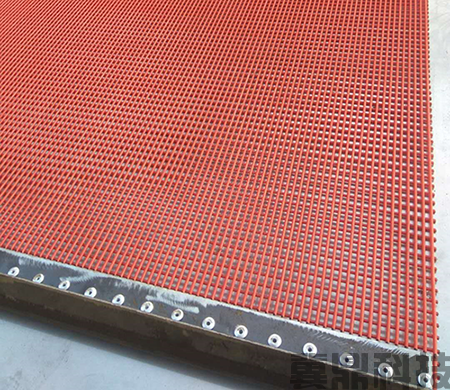

Polyurethane screens are becoming more and more popular. Why do more and more people choose polyurethane screens? What are its advantages, we and polyurethane screen manufacturers together to understand the following:

Mineral polyurethane screen refers to the use of mulberry silk, silk or synthetic fiber and other raw materials, the surface has a uniform and stable porosity, used for screening and filtration of industrial fabrics. Metal wire mesh, also known as metal wire mesh, is a large silk fabric made of silk, chemical fiber, metal wire, etc. It has the characteristics of wear resistance, corrosion resistance and high temperature resistance. No shrinkage or expansion during use.

The service life of polyurethane screens is 8-10 times higher than ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is currently the world's best wear-resistant screen surface material. High screening efficiency. The self-cleaning performance of the screen surface does not block the holes and the screening efficiency is high. Due to the strong water permeability of polyurethane and the large cone angle (140 °), it can effectively prevent the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine particles.

Has a wide range of application and stronger professional applicability. It is suitable for any type of vibrating screen machine and can be made by measuring machine. Polyurethane mesh is professionally used in hydropower stations, building materials and other metal beneficiation mining. Polyurethane has a low density (1.32kg / m 3) and is lighter than the metal screen surface, which can reduce the production unit consumption, so it can adapt to the large-scale development requirements of the screen machine.

High screening accuracy. The production process of the polyurethane screen adopts the mold casting molding process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can well meet the requirements of the user. It is easy to install and easy to replace and overhaul. This product is suitable for any type of sieving machine. It is light in weight. It is replaced and overhauled for on-site installation or polyurethane screen, which greatly reduces the workload.

Usage of polyurethane screen: Depending on the raw materials used, there will be products with different properties, usually polyester and polyether. Can be used to make plastics, rubber, fibers, rigid and flexible foams, adhesives and coatings.

Other filters, such as filters, are not easily blocked by particles, are easy to clean, and have a long service life. The main markets are gas-liquid filters, nylon mesh, industrial filters, wire mesh and fiberglass mesh. It is versatile. The demand for screens in other industries is huge, so the market is very strong.

In fact, all sieves can achieve high efficiency, but why do more and more people choose polyurethane sieves? Today, we will introduce the advantages of polyurethane screens. Long service life and large carrying capacity. Because polyurethane elastic screen is made of steel wire rope, polyurethane itself has high elastic modulus, high impact absorption and high wear resistance, so it has high tensile strength and its load-bearing capacity is rubber screen. More than 2.5 times.

The service life is 8-10 times that of ordinary metal wire mesh, 3 times that of stainless steel mesh, and 3.9 times that of natural rubber. It is a good screen surface material. High screening efficiency. The self-cleaning performance of the screen surface is not hindered, and the screening efficiency is high. Due to the strong water permeability of polyurethane and the large cone angle (140 °) of the mesh, it can effectively prevent the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine materials.

Has a wide range of applications and strong professional applicability. It is suitable for any type of vibrating screen machine and can be manufactured by a measuring machine. Polyurethane screens are used in hydropower plants, building materials and other metal mining industries. Polyurethane has a low density (1.32kg / m3) and is lighter than the surface of the metal mesh, which can reduce the consumption of the production unit and can meet the large-scale development requirements of the screening machine.

High screening accuracy. The production process of the polyurethane screen adopts the die-casting process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can meet the user's requirements well. Easy to install, easy to replace and maintain. This product is suitable for any type of screening machine. It is light-weight and can be replaced by on-site installation or polyurethane screen, which greatly reduces the workload.

Various models of mine polyurethane screens, high-frequency screens, polyurethane screen plates and other screen products produced by Chai Shang Trading Company have currently established long-term supply relationships with many domestic enterprises to Good corporate reputation has won widespread praise and trust from users, and you are welcome to call us.