Where is the polyurethane screen suitable for?

Writer: admin Time:2020-05-08 14:40 Browse:℃

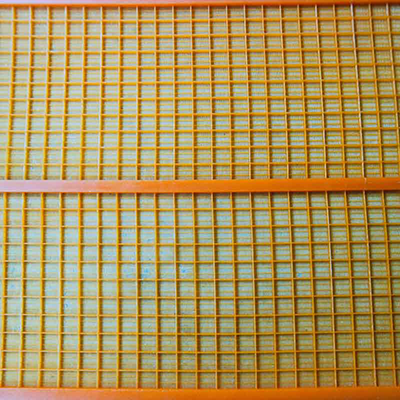

Where is polyurethane screen suitable? Let's take a look together with polyurethane screen manufacturers: Polyurethane screen refers to the use of mulberry silk, silk or synthetic fiber and other raw materials, the surface has a uniform and stable porous, with the screening and filtering function of industrial fabrics. Wire mesh, also known as wire mesh, is a large silk fabric made of silk, chemical fiber, metal wire, etc. It has the characteristics of wear resistance, corrosion resistance and high temperature resistance. It will not shrink and expand during use.

Other screens, such as filters, are not easily blocked by particles, easy to clean, and have a long service life. The main markets are vapor-liquid filters, nylon meshes, industrial meshes, wire meshes, glass fiber meshes, etc. The range of use is very wide. The demand for screens in other industries is huge, so the market is strong.

The domestic screen equipment industry has been developing, and is developing in every corner of our country. Nothing can go smoothly, and you will encounter unexpected problems of one kind or another. Mainly used in aviation, aerospace, printing, printing and dyeing, electronics, mining, pharmaceutical, food, food processing, chemical industry and other industries.

Four steps to produce polyurethane screen

1. First select the steel used to make the polyurethane screen. High-precision mold design is required before manufacturing begins. The quality of the product mold plays a key role in the quality of the punching plate.

2. Trim the sieve plate. If during the manufacturing process, the edge position of the sheet may meet the tolerance range required by the customer, the professional production technician will cut off the excess edge according to the customer's specific requirements.

3. Cutting sieve plate. The process is to cut the appropriate size from the entire roll of sheet material.

4. Level the sieve plate. Professional operators need to use a leveling machine to level the stamped deformed sieve plate to restore the original flat state. Generally, it is necessary to smooth the steel plate with a thickness of 0.8mm to 12mm and clean the stamped parts. This requires the use of suitable lubricants for lubrication and the removal of oil marks on the surface. Clean and make the punching plate look cleaner. During the entire process of forming and deep processing, unless the customer's requirements require subsequent processing, a series of subsequent processing operations should not be performed on the screen plate.

Chai Shang Trading Company can produce all kinds of mine vibrating screens, construction screens, oil vibrating screens, chemical screens, asphalt mixers, special screens for sulfuric acid compound fertilizers, railway and road networks. The production enterprises in the screen equipment industry have the scale to produce various products, leading to the market production market. The competitiveness continues to increase, and enterprises face the dilemma of how to seize the market.