Broken wire of manganese steel screen

Writer: admin Time:2020-08-25 14:28 Browse:℃

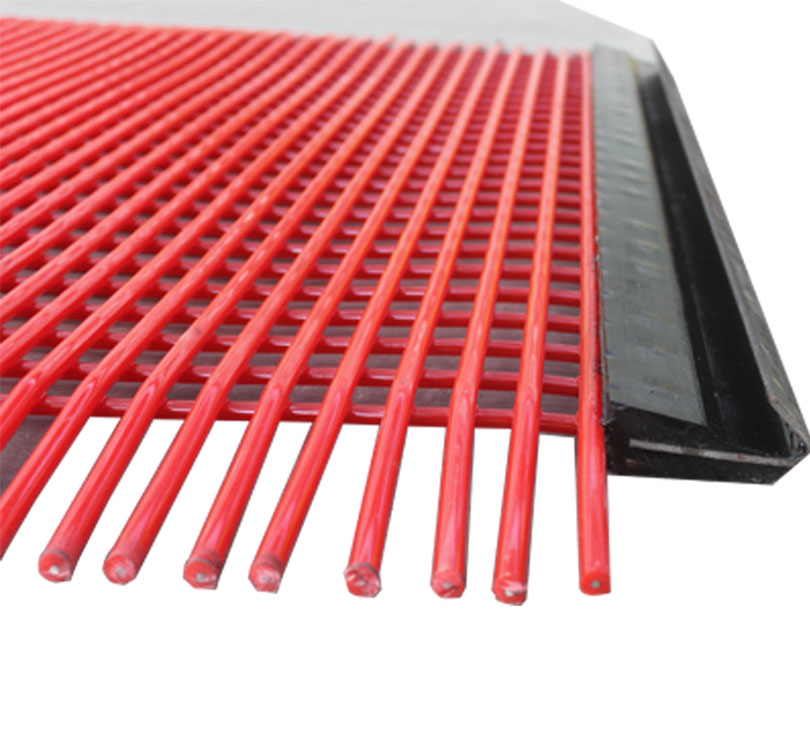

Everyone knows that manganese steel screen is a kind of metal mesh structure accessory used for screening and filtering. It is widely used in screening, filtration, dewatering, desliming and other operations in many industries. Because of its high strength, rigidity and load-bearing capacity, it is deeply favored by screening companies. But in the actual screening process, the broken wire of part of the manganese steel screen on the screen surface is miserable. Today we will come to understand with polyurethane screen manufacturers:

First of all, let’s talk about the reason for the broken wire of the manganese steel screen on the screen surface. The main reason is that the merchants are shoddy. The manganese steel wire is replaced by black steel wire. Because the black steel wire is not stretched enough in the process of processing, it is easy to break at the bending place. wire.

In the actual use of the screen, if it is found that the screen is abnormally damaged prematurely, such as a straight line fracture, we should pay attention to it. This is probably due to the formation of the screen and the support of the screen box without tension. The secondary vibration of the strips is caused by mutual impact. The reasons for this damage are as follows:

1. The tension mechanism of the screen machine is unreasonable; the solution is to reform the tension mechanism. The manganese steel screen processing enterprise technology is not good enough. During the production process, the crimping machine impresses the manganese steel wire too deeply and damages the raw material too much. After a certain period of screening, the screen surface must be broken. This is also the manganese wire break. one of the reasons.

2. The screen size is too long, causing the tensioning screw to not be tight; the solution: shorten the screen to a suitable size. When you choose a screen, you must measure the size that matches the screen, such as the length and width of the bottom edge of the screen, the angle between the folded edge of the manganese steel screen and the screen surface, and the length and width of the folded edge. Be clear and careful. In order to reduce costs, some screening companies do not purchase matching manganese steel screens from screen customization companies, but directly purchase from screen manufacturers. This can easily lead to irregular manganese steel screen sizes and lead to the screening process. Broken wire phenomenon in the middle.

3. Part of the screen box support bar is lower than the screen, and the support bar and the screen mesh surface form a gap. When the screen box is vibrating, the screen and the screen box support bar collide with each other and cause fracture; solution: transform the screen box support bar to make It reaches a reasonable height. The purpose of folding the edges of the manganese steel screen is to make the screen surface flat by the bracing hook of the screen machine. However, in the actual process, some screening companies have modified the screen machine, resulting in the manganese steel screen brace being too small. In the screening process, the impact of the material due to the manganese steel screen bracing is too small, which will easily lead to the impact of the screen surface. Uniformity, resulting in wire breakage of the manganese steel screen.

4. The manganese steel screen is too tight. The first step in debugging the screen is to make the manganese steel screen flat. This process only needs to be leveled. Don't be too tight. Too tight will have the opposite effect.

5. One reason is that in order to improve the efficiency of the operation, the screening company added too many materials to screen, which caused the screen surface to sink. In addition, the manganese steel screen support bars of the vibrating screen machine were too few, and the screen surface manganese steel wire would also appear.的rupture.