Correct installation of polyurethane screen

Writer: admin Time:2020-04-08 14:19 Browse:℃

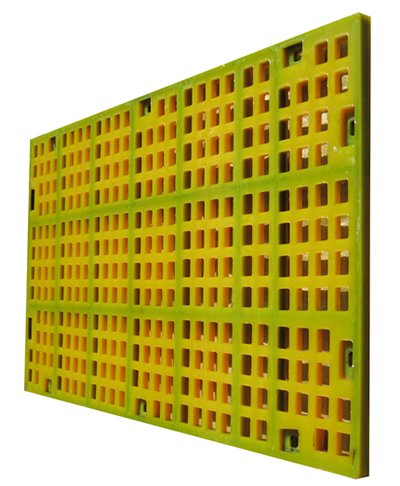

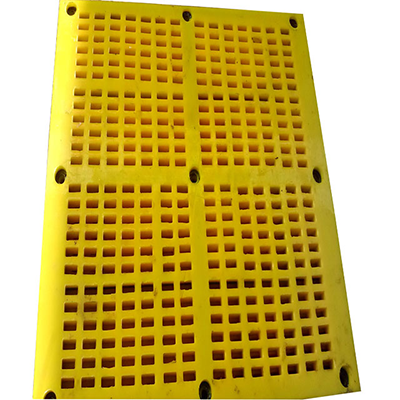

According to the structure of the 610 polyurethane screen plate, there are four types: inlaid bolt connection bead line connection screen mesh hook connection.

For example, the type of bead connection: first put the screen plate on the screen surface, and then install it according to the support beam structure of the screen. Generally, on both sides of the sieving machine, a U-shaped long iron plate of appropriate length should be drilled along the upper layer of the screen plate in the feeding direction, and drilled at an appropriate distance, and then use the bottom support beam to tighten the screen plate firmly in the middle. The contact surface of the support beam and the slender iron plate with the sieve plate is filled with rubber strips (use old rubber hose). It can also be installed in this way above the support beam in the middle of the screen.

Polyurethane sieve plate structure is divided into four types: inlaid bolt connection bead connection sieve hook connection. Then install according to the support beam structure of the screen. Generally, on both sides of the screen machine, the upper layer of the sieve plate should be drilled with a suitable width u-shaped long iron plate at an appropriate distance in the direction of the material, and then bolted to the bottom support beam to tighten the sieve plate Fixed in the middle. The contact surface between the supporting beam of the mining polyurethane screen plate and the long iron plate and the screen plate is preferably lined with rubber strips (the old hose can be used). Above the support beam in the middle of the sieve can also be installed in this way.

For example, bead connection type: Please put the sieve plate on the sieve surface, and then install it according to the support beam structure of the sieve. Generally, on both sides of the screen machine, the upper layer of the sieve plate should be drilled with a suitable width u-shaped long iron plate at an appropriate distance in the direction of the material, and then bolted to the bottom support beam to tighten the sieve plate Fixed in the middle. The contact surface of the support beam and the long iron plate and the sieve plate can be lined with rubber strips (old rubber hoses can be used). Above the support beam in the middle of the sieve can also be installed in this way.

If the screen plate is not installed as required, it may be shaken up and down on the screen surface, and a long-term friction collision with the steel support beam will seriously affect the service life of the screen plate.

1. Specification:

(1). The standard type in the table is a common item, and its screening efficiency and service life are moderate; the efficiency type efficiency is slightly higher and the life is slightly lower; the life type efficiency is slightly lower and the life is higher.

(2). The screen size in the table generally refers to square holes, polyurethane screen plate, if you need rectangular holes or other hole shapes with different sizes, you can contact the company to produce.

2. Product features:

(1). The horizontal and vertical strips of the screen are made of high wear-resistant polyurethane material, and the strips contain steel wires. The service life is 3-10 times higher than the traditional metal screen.

(2). Unique structure, suitable elasticity and plastic force, can not only reduce jamming, but also reduce sticking due to the second harmonic high frequency vibration of the screen strip. High practical opening rate and high screening efficiency.

(3). There are elastic tensioning hooks on both sides of the screen. The overall weight is light, the flexibility is good, the transportation and storage are easy, and the installation and disassembly are convenient.

The polyurethane elastic screen fully utilizes the excellent wear resistance of the polyurethane elastomer, high strength, high elongation and high elasticity in a wide hardness range. The polyurethane foam is then bolted to the bottom support beam. 2 Good shock absorption performance and oil resistance , Low temperature resistance, heat aging resistance, radiation resistance, electrical insulation and other properties.

1. Good abrasion resistance and long service life. Its abrasion resistance is 3 ~ 5 times that of steel sieve, and more than 5 times that of ordinary rubber sieve.

Seal polyurethane screen: can be 0.2mm13mm, dewatering screen can be used for more than 6 months and 12 months at a time. Polyurethane screen,

2. The maintenance workload is small, the polyurethane screen plate is not easy to damage, and the service life of the mining polyurethane screen plate.

If the sieve plate is not installed as required, it may cause it to shake up and down on the surface of the sieve, and the friction and collision with the steel support beam for a long time will seriously affect the service life of the sieve plate.

1. Specifications:

(1) The standard types in the table are ordinary products, and the screening efficiency and service life are medium; the efficiency type is slightly higher and the service life is slightly lower; the life-type efficiency is slightly lower and the service life is longer.

(2) The mesh size in the table generally refers to square holes, polyurethane sieve plates, if you need different square holes or other shapes of holes, you can contact our company for production.

2. Product features:

(1) The longitudinal and transverse strips of the screen are made of highly wear-resistant polyurethane material, and the steel wire contains steel wire. The service life is 3 to 10 times that of traditional metal mesh.

(2) Unique structure, suitable elasticity and plastic force can not only reduce paper jam, but also reduce sticking caused by high frequency vibration of the second harmonic of the screen. The utility model has high opening rate and high screening efficiency.

(3) Both sides of the screen have elastic tension hooks. The whole machine has light weight, good flexibility, easy transportation and storage, and convenient installation and disassembly.

(4) The screen can effectively absorb impact force, reduce noise and improve working environment.

Metallurgy (iron ore, limestone, fluorite, cooled blast furnace slag, coke and other raw materials), non-ferrous, yellow, coal, chemical, building materials and hydropower engineering, abrasive waste treatment, quarry and other industries, washing and screening, classification And other industries.

Various size and mesh sizes of the new structure mode screen plate is particularly suitable for applications with high impact, high hardness and high wear resistance. Wear-resistant sieve plate, used for fine crushing and sieving of iron ore, classification of raw coal, gold, building materials, and sieving of gravel for hydropower and nuclear power engineering.