Maintenance of polyurethane screen

Writer: admin Time:2020-04-10 15:06 Browse:℃

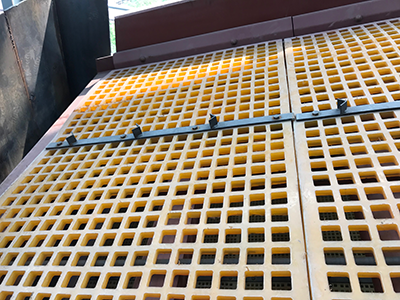

The maintenance and repair work of polyurethane screen is very important. It not only relates to the life of the equipment, but also has a great influence on the output quality of the dried product. In the maintenance process, how should we adjust the screen of the dryer to improve work efficiency? Today, polyurethane screen manufacturers will introduce the daily maintenance of polyurethane screens.

Let's start with the polyurethane screen of the dryer of the drying equipment and explain how to achieve the purpose of improving efficiency through the adjustment of the polyurethane screen.

Take the slime dryer as an example: when installing the polyurethane screen, the burr side of the screen hole should be facing inward and the smooth side facing out. The screen and the frame should be tightly fitted. When installing the ring screen, the screen The stubble in the inner layer should follow the direction of rotation to prevent the material from getting stuck at the overlap. And in the production process, according to the production needs, adjust the screen.

First, increase the vibration amplitude;

Second, use sprayed water to flush the screen and drill cuttings to reduce the viscosity of drill cuttings, but this method is only suitable for the occasions where water is allowed to be added;

3. Adjust the angle of the screen at the end of the sand outlet downward, which is helpful for the cuttings to be discharged by gravity, but it may cause slurry rush;

Fourth, replace the mesh of the polyurethane screen or adjust the flow rate of the single screen to ensure that the flow stop point of the drilling fluid is close to the screen outlet, so that the cuttings are smoothly discharged under the lubrication of the drilling fluid.

Through the above adjustments, the operation process of the dryer will be smoother, and the quality of the finished products will be improved. The above is simply to start with the adjustment of the screen. There are more maintenance details that need everyone ’s attention and interest Of friends often browse relevant information on our website.

Polyurethane screen 1. Pump assembly of horizontal sand mill: The connection key of the gear pump and the CVT is made of nylon material. The key is cut off in case of overload or blockage of the gear pump to protect the CVT and the gear pump.

II. Replace the horizontal sand mill's dispersing disc and village sleeve: when the disc has been worn or partially worn and needs to be replaced or assembled again, first move the cylinder, and then remove the hexagonal screws and parts one by one. When assembling, the new or less worn dispersion disc should be installed in the innermost position, and pay attention to the installation of the village cover according to the original position, so that the efficiency and the service life of the polyurethane screen can be extended.

3. Replace the seal of the horizontal sand mill:

1. Open the cylinder;

2. Loose disk assembly and remove the screen.

3. Clean the shaft with agent, and remove the front cover and discharge cover of the cylinder.

4. Two elastic rubber hoses, remove the discharge tray.

5. Sealing ring, when removing the sealing ring, remember not to use gravity and collision.

6. The lower washer and bearing protection device must be carefully cleaned after all parts are lowered, especially the moving ring and static ring must be cleaned to ensure that they are spotless.

7. Install mechanical seal.

8. Install the bearing protection device.

9. The spring is installed in the small hole of the bearing protection device, and adhered with a little grease to keep them in the correct position.

10. Install the washer and O-ring, and then install the moving ring, and make the washer against the small spring, and check whether the O-ring device is correct, and whether the pin of the bearing protection device passes through the hole of the washer and moving ring seat.

11. Install the tray, and check to make it in the correct position.

12. Then connect the rubber tube. Polyurethane screen

13. The front end of the cylinder is installed on the machine base and check whether the scraper position is completely in the middle position, otherwise it should be adjusted to the center.

14. The screen and dispersing disc are assembled on the shaft.

15. Turn the shaft by hand to maintain a 0.4 mm gap between the inner blade and the outer blade.

16. Body and check whether the position of lubricating fluid is correct.

IV. Maintenance inspection of horizontal sand mill:

1. During operation, the circulation of lubricating fluid can be ascertained through the sight glass and piping, and corresponding measures can be taken.

2. The circulation of cooling water.

3. The lubricating oil of the ball inorganic transmission should not be lower than the centerline position on the oil mark.

4. Overhaul should be done once a year or so.

5. The gauge exceeds the normal pressure, which proves that the machine is malfunctioning, and the accumulated material in the machine blocks the screen ring. It should stop working and remove the cylinder to clean the screen ring.

Daily maintenance:

1. Before starting: (A) Check whether the screen is damaged or not (B) Whether each group of ring is locked;

2. When starting: (A) Note whether there is abnormal noise (B) Whether the current is stable (C) Whether the vibration is abnormal;

3. After use: Clean up after each use.

Regular maintenance:

1. Regularly check the thick and thin nets and springs for fatigue and damage, and check whether various parts of the fuselage are damaged due to vibration.

2. The motor has been running for about two weeks, and the lithium-based grease must be replenished at the right time.

(ZL-3). Accumulatively run for 1500 hours, check the bearings, and clean them up if damaged.