Cyclone inspection and maintenance methods

Writer: admin Time:2020-07-29 15:24 Browse:℃

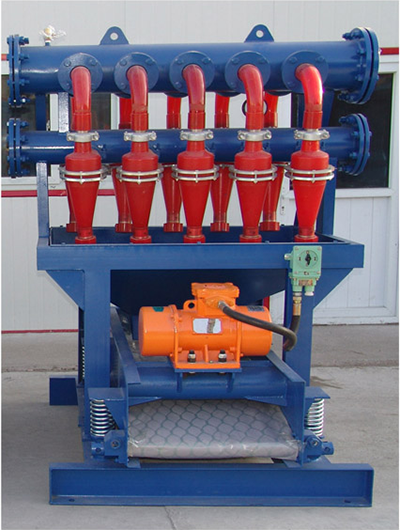

Wear resistance is mainly used in power, kerosene, chemical, metallurgy, mining, sewage treatment and other industrial fields, especially under harsh operating conditions such as high wear, strong corrosion, high temperature, and high pressure, showing its superiority. In order to ensure that the cyclone unit will not have unexpected failures during use, causing missed work and hours, and also to extend the service life of the equipment, daily inspection and cleaning should be strengthened. Below we will work with the cyclone manufacturer to understand the inspection and maintenance of the lower cyclone:

It is necessary for cyclone to use this technology for the aging treatment of the engineering seat. This process is based on years of experience. Its purpose is not only to make pottery and porcelain completely stable, but also to have more advantages. Under various messy conditions, it is necessary to maintain the stability of these two combinations. The seals and wearing parts of the valve are made of high-tech new ceramic structural materials, which improves the wear resistance, corrosion resistance and sealing of the valve products, and greatly extends the service life of the valve.

1. Preparation before maintenance:

⑴ The maintenance plan should be made based on the equipment problems found in the spot inspection.

⑵ According to the maintenance plan, the spare parts, materials and construction personnel should be confirmed, and the cyclone should be assembled for use in normal times.

⑶ Workers on the job should wash the cyclone and surrounding minerals.

2. Overhaul period and scope:

⑴ The overhaul of the cyclone is only a minor repair, which can be arranged at any time according to the state of the cyclone.

⑵ Minor repair scope: replace it with a cyclone, or replace the elbow, cover, and cone compensation, replace the overflow pipe and grit nozzle, etc.

3. Technical requirements for maintenance:

⑴ The caliber of the grit nozzle and overflow pipe should meet the requirements of the production process, and should be replaced in time when worn.

⑵ It is necessary to ensure that all parts are not leaking, not clogged, and the snail body is not severely worn.

⑶ The overhauled or replaced cyclone should overflow and not run thick when in use, and the sand should be sprayed in an umbrella shape.

⑷ The center line of φ500 cyclone valve G1/2" hole and the center line of cone 4 holes φ20 are at an angle of 15° with the assembly center line. The center line of φ350 cyclone cone 4 holes φ18 is 12 with the assembly center line °Angle.

4. Test run acceptance

(1) After the maintenance, the maintenance workers and the post workers jointly conduct a trial operation.

(2) The maintenance workers must clean up the site before trial operation.

(3) Trial operation should meet the following conditions:

①There is no leakage in all parts of the cyclone.

②There is no blockage and debris in the cyclone.

③The cyclone runs smoothly, without vibration and humming.

The daily regular inspection of the cyclone group is as follows:

1. Check whether the bolts used in each part of the equipment are loose and whether the installation is complete.

2. The condition of the outlet of the cyclone should be checked to see if there is any blockage. Some cyclones will vibrate violently due to blockage.

3. Check whether the connections of the various equipment in the cyclone group are normal, and whether there is any leakage.

4. Carefully check the wear of the grit port and overflow port of the equipment to see if it can continue to be used and does not need to be replaced.

5. Check whether various gates, such as pneumatic gates, are flexible in use, which has an effect on the overall operation of the equipment.

6. Check the operation of the air compressor of the cyclone unit, whether there is any abnormal vibration, whether the parts are overheated due to continuous use.

7. Also check whether the air path of the air compressor is running smoothly and whether there is any air leakage.

8. Various lighting and protective devices should be checked one by one to prevent accidents during work.

9. Clean up the sundries in each part of the cyclone group to prevent the cyclone from affecting the work.

In addition to daily inspections, the equipment must be cleaned daily to ensure that the equipment is clean and hygienic. The operation will not be affected by foreign objects. If there is an oil leak, it must be cleaned. There should be no accumulation on the cyclone group. Gray phenomenon.