Friction between polyurethane screen and various materials

Writer: admin Time:2020-07-28 16:50 Browse:℃

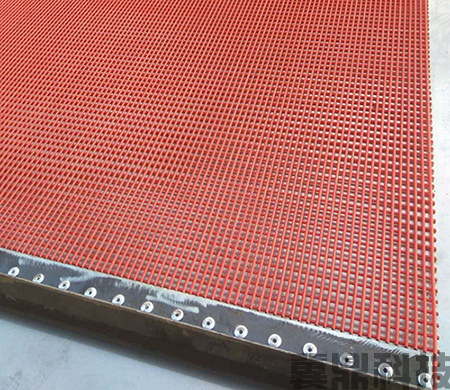

The polyurethane screen production process is usually used in vibrating screen equipment. There is also friction between machines and equipment. Polyurethane screen manufacturers will introduce the friction between various materials and polyurethane screens.

Under the action of external force, when two closely contacting objects move or have relative movement tendency, the resistance between the contact surfaces will be hindered. This phenomenon is called friction. Only when the relative motion trend is called static friction, the magnitude of static friction changes with the external force acting on the object; when the external force overcomes a large static friction force, the friction force when the objects move relative to each other is called dynamic friction force.

Polyurethane screen manufacturers: According to the different motion forms of the two moving objects, dynamic friction is divided into sliding friction and rolling friction. According to the friction state, that is, surface contact conditions and oil film thickness, sliding friction can be divided into four categories, namely dry friction, boundary friction (boundary lubrication), fluid friction (fluid lubrication) and mixed friction. (Mixed lubrication).

1, dry friction

The friction when two friction surfaces are in contact with pure metal without any lubricant or protective film is called dry friction. Of course, the production of polyurethane screens is also dry friction. In engineering practice, there is no real dry friction, because any part of the surface exposed to the atmosphere will not only form an oxide film due to oxidation, but will also be more or less wetted or "contaminated" by lubricating oil. When the friction coefficient is used, the friction coefficient will be significantly reduced. In mechanical design, friction that does not exhibit significant lubrication is usually regarded as dry friction.

2, boundary friction

The friction surface is attached to each of the two friction surfaces, and the friction state where the two surfaces are still in contact with the peak is called boundary friction. Compared with dry friction, the friction state of boundary friction has been greatly improved. The degree of friction and wear depends on the properties of the boundary film, the mechanical properties of the material surface and the surface morphology.

3, fluid friction

Polyurethane sieve plate manufacturer: The friction where the two friction surfaces are completely separated by a layer of fluid (liquid or gas) and the surface peaks are not in direct contact is called fluid friction. Fluid friction will not cause wear on the metal surface, which is an ideal friction state.

4. Mixed friction of polyurethane screen

There is dry friction between two surfaces at the same time. The state of boundary friction and fluid friction is called mixed friction.