Screens commonly used in mining

Writer: admin Time:2020-09-17 13:48 Browse:℃

As the main wearing parts of the vibrating screen, the screen is mainly used for filtering, screening, dewatering, desliming and other operations. Direct contact with the material during the production process, once the material is selected improperly, it is easy to damage too quickly. At present, the material of the screen is mainly divided into two kinds: metal and non-metal. Metal materials include low-carbon, high-carbon, high-manganese steel, stainless steel, etc., and non-metal materials are mostly rubber, nylon, polyurethane, etc. Of course, different mine screens have different characteristics, materials, and uses. In order to make the correct choice for everyone, polyurethane screen manufacturers introduce the performance characteristics of several common mining screens.

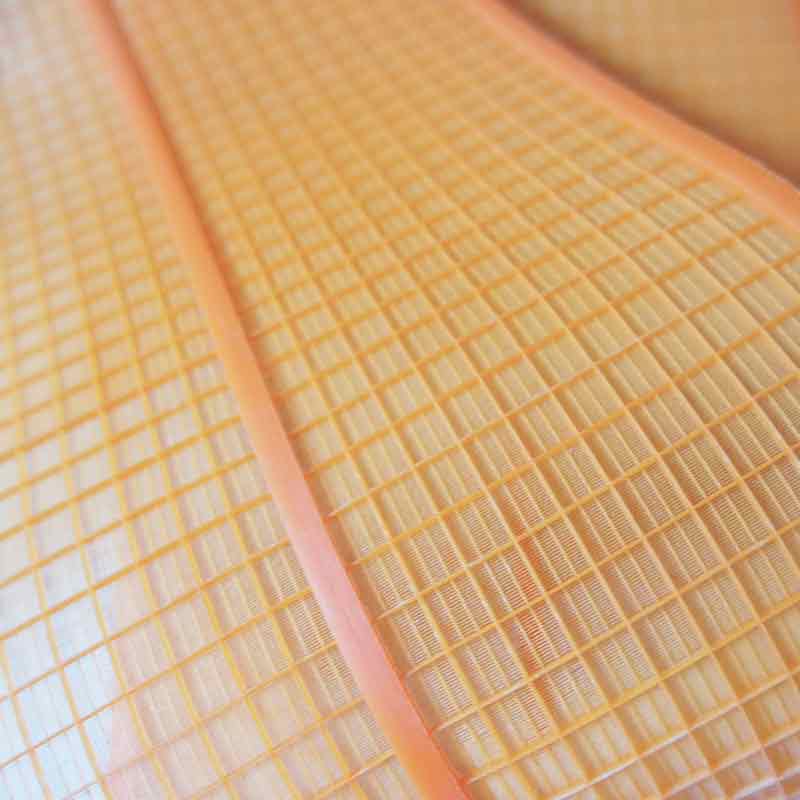

One, polyurethane screen

Polyurethane screens are also easier to use and have better wear resistance. Polyurethane itself has very high elastic modulus, high strength and impact absorption, high wear resistance, and high tensile strength, so its bearing capacity is relatively high. It is more than 2.5 times that of rubber sieve plates, and its service life is 8-10 times longer than that of ordinary metal sieve plates, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is the current screen material with better wear resistance. . The production material of the polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flexibility resistance, and large bearing capacity, and has been specially treated to ensure that it will never delaminate under long-term alternating loads.

is divided into four types according to the structure of polyurethane sieve plate:

1) Mosaic

2) Bolt connection

3) Bead connection

4) Screen hook connection

Advantages of Polyurethane Screen

1. Long service life and large carrying capacity.

2. High screening efficiency. The screen surface has self-cleaning performance, no hole blocking, and high screening efficiency.

3. Wide range of application, stronger professional applicability, suitable for any type of vibrating screen machine and can be manufactured by measuring machine.

4. High screening accuracy. The production process of the polyurethane screen adopts the mold casting process, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can well meet the user's requirements.

5. Low working noise, in line with national environmental noise standards.

6. Significant economic benefits. Although the price of polyurethane rubber screens is higher than that of metal screens, if you comprehensively consider factors such as screening efficiency, maintenance costs, and service life, you will find that the overall benefits of polyurethane screens are much better than ordinary metal screens.

Two, high manganese steel screen

Among the many materials, the reliable quality is high manganese steel screen. It is a screen product woven by manganese steel mesh wire with a diameter of 1.6mm-12mm. It adopts an embedded weaving method. The overlapping points of warp and weft are not prominent. The screen surface is flat and the force is even. Plasticity and toughness can achieve better results, and the service life is more guaranteed.

High manganese steel has high strength, rigidity and bearing capacity. When subjected to strong impact and friction, the surface will produce strong work hardening due to plastic deformation, and the surface hardness can be increased to above HRC60, thereby obtaining high wear resistance , While the interior still maintains high plasticity and toughness.

In addition, when the old surface is worn out, the new surface will form a wear-resistant layer, so the service life can reach 4-8 times that of ordinary screens. It is mostly used in large-scale mining industries. It can also be used as a protective net for mechanical vibrating screens, Drum screen machine, electromagnetic high frequency screen machine and asphalt mixing machine, etc.

Three, stainless steel screen

The stainless steel screen material mainly includes 201, 201, 302, 304, 304L, 316, etc., with the following characteristics:

Good acid, alkali and rust resistance;

High strength, strong tensile force, toughness and abrasion resistance, durable;

High temperature oxidation resistance, 304 stainless steel screen has a nominal temperature resistance of 800℃, and 310S stainless steel screen has a nominal temperature resistance of 1150℃;

Normal temperature processing, that is, easy plastic processing, diversifying the use possibilities of stainless steel screen;

High smoothness, no surface treatment required, easy maintenance.

Stainless steel screens are often used for screening and filtering under acid and alkali environmental conditions, as well as mud screens in the petroleum industry and screen filters in the chemical and chemical fiber industry.

Four, punching screen

Punching screen refers to the screen that uses a punch to punch out the target pattern in the plate to be processed. Generally, it is made of stainless steel, aluminum plate, cold and hot steel plate, copper plate, PVC plate film and other materials. Holes, square holes, round holes, hexagonal holes, scale holes, stretched shaped holes, etc.

perforated screen has the characteristics of light weight, non-slip, beautiful appearance, good filtering performance, etc. It is often used in environmental protection noise control barriers in traffic and municipal facilities, grinding screens, mine screens, I-shaped screens, etc. for mines.

The screen material is a point that many users will emphatically consider when choosing a vibrating screen, because it is largely related to the service life of the equipment and the later cost input. If the selection is not appropriate, it will accelerate the wear of the screen and affect the normal Production increases the cost of parts, so users must pay attention when choosing screen materials, and try to choose products that are wear-resistant and have good results.

Through the introduction of Chaishang Trading Company, we can understand that there are so many kinds of screens according to the material, and different kinds have different properties and characteristics, so the purpose of each different material screen is also different, we have to choose Suitable for yourself.