Features of bar screen

Writer: admin Time:2020-09-25 15:20 Browse:℃

What are the main characteristics of the polyurethane rod screen? Today, polyurethane screen manufacturers will give a brief introduction:

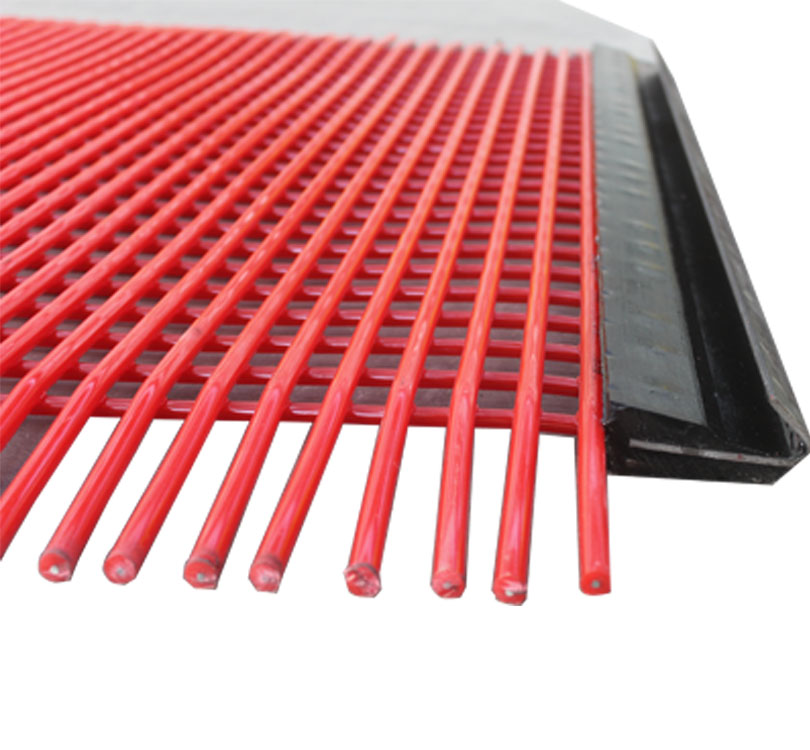

Polyurethane rod screens make full use of the elastic properties of polyurethane materials, which mainly reflect the abrasion resistance, high strength, high elasticity and other properties of the screen, and have good shock absorption, oil resistance, aging resistance, and insulation properties. After continuous research, several reasonable additions have been made to modernize the design and structure of the screen holes.

1. Features of polyurethane rod screen:

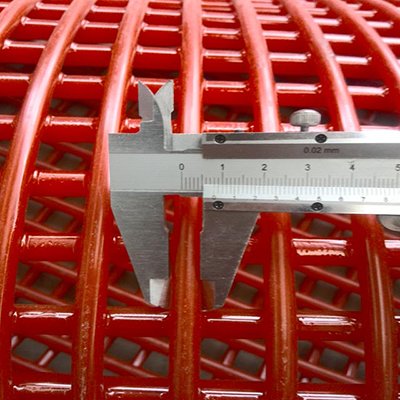

Polyurethane bar screen: can be 0.2mm-13mm, the dewatering screen can be used for 6 months-12 months at a time.

Polyurethane rod screen: It has a very good effect for coke, high screening efficiency and wear resistance. The screen can be used for 6 months at a time.

1. Good abrasion resistance and long service life. Its abrasion resistance is 3 to 5 times that of steel screens and more than 5 times that of ordinary rubber screens.

2, the maintenance workload is small, the polyurethane screen is not easy to be damaged, and the service life is long, so it can greatly reduce the maintenance volume and the loss of maintenance.

3. The total cost is low. Although the polyurethane screen of the same size (area) has a higher one-time investment (about 2 times) than that of the stainless steel screen, the life of the polyurethane screen is 3 to 5 times that of the stainless steel screen, and it is repaired and replaced. The number of times is small, so the total cost is not high, and it is very economical.

2. Working principle of polyurethane bar screen:

The high-frequency tuning fork of the bar sieve plate, while vibrating with the sieve plate, generates secondary high-frequency resonance, which speeds up the advancement of materials and accelerates the sinking of particulate materials on the screen surface and the small particles that have contacted the screen surface The speed of lateral movement to the sieve hole increases the probability of passing through the sieve hole. The opening of the sieve plate can reach up to 80%. The sticky matter with a certain amount of moisture will shake off by its high-frequency self-vibration, and it is not easy to stick to it. The sieve bars cause blockage and are the most ideal sieve plates for difficult-to-screen materials that are viscous or contain fibrous materials. Third, the use of polyurethane rod screen:

The bar screen is mainly used in metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), coke, coal, coal washing, chemical industry, building materials and hydropower engineering, abrasive waste treatment, quarry and other industries Materials washing, screening, grading and other industries. The new structure pattern sieve plate with various format specifications and sieve hole sizes is especially commonly used in occasions with strong impact, high hardness and high wear resistance. Wear-resistant screen plates are used for fine crushing and screening of iron ore, raw coal classification, gold, building materials, and sand and gravel screening for hydropower and nuclear power projects.

Fourth, the advantages of polyurethane rod screen:

1. The structure of the cantilever, coupled with the performance of the material of the bar screen parts, so this screen has a higher separation efficiency.

2. The single-layer double-sided self-cleaning bar sieve plate can ensure that the particles below 5mm into the furnace are less than 5%.

3. It can meet the ever-increasing requirements of blast furnaces to eat fine materials.

4. Long service life.

Polyurethane rod screens are mainly used in metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), coke, coal, coal washing, chemical industry, building materials and hydropower projects, abrasive waste treatment, quarries, etc. Industries such as washing, screening and grading of industrial materials. The new structure pattern sieve plate with various format specifications and sieve hole sizes is especially commonly used in occasions with strong impact, high hardness and high wear resistance. Wear-resistant screen plates are used for fine crushing and screening of iron ore, raw coal classification, gold, building materials, and sand and gravel screening for hydropower and nuclear power projects.

Polyurethane bar screen has a long service life and large carrying capacity. Because the polyurethane elastic screen uses steel wire as the skeleton material, and the polyurethane itself has a very high elastic modulus, high-strength impact absorption, high wear resistance, it has high tensile strength, and its load-bearing capacity is rubber screen More than 2.5 times. Compared with ordinary metal screens, its service life is increased by 8-10 times, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is currently the world's best wear-resistant screen material. The production material of the polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flexibility resistance and large load-bearing capacity. The raw materials for the production of polyurethane screens have been specially treated to ensure that they will never delaminate under long-term alternating loads.