Classification of high frequency screens

Writer: admin Time:2020-10-12 10:46 Browse:℃

Polyurethane High frequency screen are classified in many ways. The most obvious characteristics of polyurethane high-frequency screens are high screening efficiency, large processing capabilities, compact and reasonable structure, small footprint, and low power consumption. The polyurethane high-frequency screen frame is supported by a rubber tension spring, which has low noise, low power consumption and small equipment dynamic load. The polyurethane high-frequency screen has no special requirements on the device foundation. How many classifications of high-frequency screen composite meshes are, let's understand together with the polyurethane screen manufacturers:

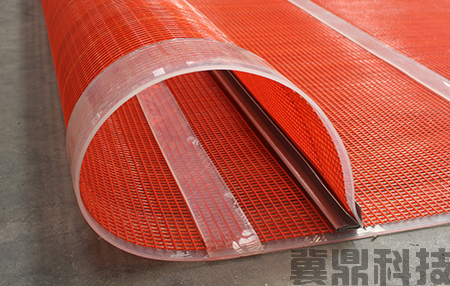

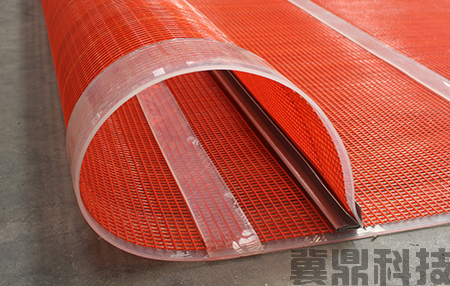

High-frequency screen composite mesh is normally divided into two layers of stainless steel mesh.

One layer is the support layer, and the other layer is the operation layer

Support layer (bottom network, offline): play a role of support and cover

Operation layer (surface network, Internet): the theoretical filter layer

Bottom net: There are 16 meshes, 18 meshes and 20 meshes that are rarely used. The material is rarely used nickel-free and 304 two kinds

Face mesh: high mesh number, most of them use 304 material, rare meshes are: 250 mesh, 220 mesh, 200 mesh, 180 mesh, 150 mesh, 100 mesh, 90 mesh, 80 mesh, 70 mesh, 60 mesh, 50 mesh, 40 mesh, 30 mesh and the like.

The screen surface is composed of three layers of opposite flexible screens. The bottom steel rope core polyurethane net is a support net, and a double-layer stainless steel wire braided composite net with different wire diameters and mesh holes is laid underneath. The lower layer of the composite net is the work net, indirect contact with the material to continue the screening operation, the composite net layer is the bottom net, used to evacuate the force and transmit vibration, to ensure the high screening efficiency of the work net and extend the service life. There are hooks at both ends of the screen to facilitate loading and unloading of the screen and adjusting the tension. The feeding buffer screen makes the slurry evacuate evenly and prevents the screen from being damaged by indirect charge. Stainless steel composite mesh, manganese steel mesh, stainless steel mesh, steel plate mesh, perforated mesh and other wire mesh products. The production of polyurethane high-frequency mesh is not only unsalable. Polyurethane high-frequency meshes exist in more than 30 provinces, municipalities and autonomous regions. The advantages of high screening efficiency, large solution power, compact and proper structure, small footprint, and low power consumption. The polyurethane high-frequency screen frame adopts rubber tension spring suspension support, low noise, low power consumption, and small dynamic load of the facility, so there is no special requirement for the device foundation. Forcing the slurry to be distributed to the ore can make the slurry spread evenly on the screen surface, increase the progress of the slurry fixation on the screen surface, and extend the life of the screen. Dual vibrator configuration, curve vibration and patented technology of re-pulping, fixed sea area for screening materials, fast transfer progress, and greater screening power and motivation. The nominal anti-corrosion and wear-resisting spray glue of the facility is solved, and the service life of the facility is invalidated.

The polyurethane high-frequency screen has a high capacity of five layers of grading screen frames. The polyurethane high-frequency screen saves space on the ground and reduces the cost of the device. The polyurethane high-frequency screen forces the pulp to be distributed to the mine, which can spread the pulp evenly on the screen surface, reduce the speed of the pulp on the screen surface, and extend the life of the screen. Polyurethane high frequency screen double oscillator equipment, linear oscillation cooperative re-pulping patent technology, screening materials have a long active area, fast transfer speed, and have greater screening ability and screening effect.

Polyurethane high-frequency screen equipment surface is treated with anti-corrosion and wear-resistant spray glue, which can extend the life of the equipment. Polyurethane high-frequency screen classification can be carried out according to the working purpose of the screen, and the polyurethane screen can be classified according to the material to be screened, but no matter which classification method is used, it is for the user to choose the polyurethane screen In time, we can directly find the suitable type and standard products according to the targeted and specific polyurethane screen classification, and then ensure the user's high efficiency.

Secondly, no matter which method the polyurethane high-frequency screen is classified according to, the operating principle and characteristics of the polyurethane high-frequency screen are the same. Any kind of polyurethane high-frequency screens are screened and filtered through multi-layer sand control filter sleeves. Therefore, the polyurethane screens have outstanding sand control properties and can well isolate the occurrence of sand blocking at the bottom layer.

At the same time, the hole distribution of the polyurethane high-frequency screen is relatively uniform, and has super penetration, which further increases the filtering area of ??the polyurethane screen. Therefore, the movable resistance of the screen will be reduced, which greatly improves the output. Oil rate. The advantages of polyurethane high-frequency screens will not change due to the different classification methods of polyurethane screens.

For example, the polyurethane high-frequency screen of any method is unlikely to show the problem of rust, and has strong anti-corrosion function, and can be used to various different application environments. The multi-layer structure of the welding points can be combined with uniform filtering holes. The structure is integrated, so that it will not be deformed, ensuring the normal function and service life.