Maintenance of Flotation Machine Impeller Cover

Writer: admin Time:2020-10-26 13:52 Browse:℃

How to maintain the impeller cover of the flotation machine? Many friends have asked this question. Indeed, improper use and maintenance will reduce the service life of the impeller cover of the flotation machine, so this is a problem that everyone is more concerned about. Today, the impeller cover manufacturer will come to talk to you. Let’s talk about these issues, and hope to help you all.

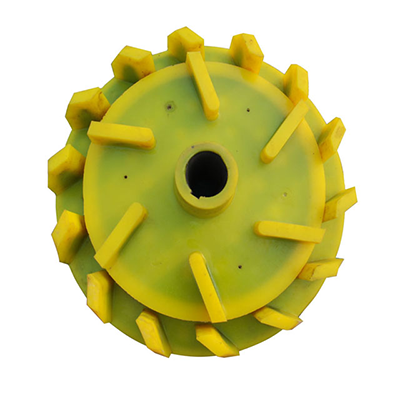

The impeller cover of the flotation machine uses the rotating impeller to fully aerate and stir the slurry in the ore tank, so that the slurry produces bubbles of different sizes, and the granular powder material in the slurry assists the formation of a mineralized layer on the bubbles during the continuous oxidation process , When the impeller cover of the flotation machine is accumulated to a certain extent, it is scraped out by the scraper to obtain the finished mineral material.

Introduction to the matching settings of the impeller cover:

1. The flotation machine uses mechanical stirring, a novel and unique slurry feeding method, reasonable slurry flow, and great processing talent;

2. High aeration efficiency, wide adjustable scale and fast flotation speed. When the machine is turned on, the air intake can be adjusted at will.

3. The stirring arrangement is an impeller with zigzag blades and a radial steady flow plate, which can make the coal slurry circulation and aeration moderate;

4. According to different coal types, particle sizes, and concentrations, the fluid dynamic parameters are optimized and planned, so that high-density, coarse and fine-grained coals can also achieve the desired sorting effect.

5. Compact structure, light weight and reliable operation. The flotation speed is fast, the selectivity to the fine particle level is high, and the coarse particle level flotation effect is good.

6. Low energy consumption and chemical consumption, installed capacity and actual power consumption are less than the same type and specification flotation machine.

7. Reasonable structural parameters, small footprint, and overall compatibility with old equipment.

8. High operational reliability, convenient operation and maintenance, single-point control of slurry level.

A steady flow plate is also installed inside the flotation machine to ensure the stability of the slurry material in the flow. When the equipment is used for a long time for timely maintenance, the cover plate and the steady flow plate are worn and damaged, the flotation machine impeller The cover plate will directly affect the flow stability of the slurry surface, resulting in the phenomenon of turning over the liquid surface, which will affect the normal production of the equipment to varying degrees.

The impeller cover is a vulnerable part of the flotation machine. The service life of the impeller cover of the flotation machine is the most concerned issue of our customers. Therefore, not only should we go to a regular professional manufacturer, but also determine the material when purchasing.

Customers should explain the usage of their factory to the manufacturer when purchasing, so that our manufacturer will adjust the degree of wear of the customer during production, such as the rubber impeller cover purchased on the market for 5 months. If there is no flower in the tank, it means that it needs to be replaced. For customers, this will cause unnecessary economic losses in the long-term. Professional manufacturers will make a rubber adjustment on the ingredients to make it more wear-resistant and extend the service life. For example, lead Zinc concentrator and molybdenum beneficiation plant, if the same impeller is used, the service life of the lead-zinc ore of the flotation machine impeller cover is much longer than the service life of molybdenum beneficiation. The reason is the ratio of reagents in the flotation cell. Different. Therefore, the customer must tell the manufacturer the specific situation when purchasing, so as to avoid unnecessary trouble.

Flotation machine is an important equipment in the flotation process. Pay special attention when buying a flotation machine. After all, buying a flotation machine with poor quality will still damage your own interests. In order to bring great benefits to friends in the mining plant Interest rate, a good flotation machine must have the least energy consumption, the strongest equipment, and the strongest wearing parts. As for the wearing parts, it must be the impeller and the machine cover.

introduces you to the abrasion problem of the impeller and cover of the flotation machine. First introduce the impeller, it must be in a high-speed rolling situation when it is produced, so its center point will become a negative pressure strength, causing air to be sucked in from the suction pipe, driving the pulp to be sucked in from the side hole and the cover hole. , Forming three streams of solid, liquid and gaseous fluids that blend with each other. Under the action of centrifugal force, these three fluids move outward together. When they pass through the cover grid, their flow velocity will suddenly change due to resistance. In this way, the fluid will be divided into several strands, and the gas phase will become fine bubbles. This production cycle makes the solid, liquid, and gas mixed into a uniform state, and becomes a mixture of ore slurry with bubbles dispersed. Due to the difference in slurry pressure distribution, movement direction, and flow rate, the wear of each part of the flotation machine impeller and cover plate varies greatly. The wear of the impeller mainly occurs on the front surface of the outer edge of the blade, the outer edge of the disc, and the bottom of the disc. The flow rate of the slurry is high, and the relative speed with the slurry is high. The direction of the streamline is changed from the direction that the impeller follows to the direction parallel to the cover grille. This change causes a large amount of wear on the slurry. First, the right angle of the upper edge is worn away. , And then proceed downward. The abrasion is caused by the relative movement of the pulp and the disk, and may also be caused by friction with the false bottom with too small clearance. Of course, the farther from the center, the higher the relative speed of the disc and the slurry, and the greater the wear caused by this. The wear of the cover plate mainly occurs on the inner edge of the grille. The flow direction of the slurry in this area is forced to change, and the inner edge is subject to fierce impact and crescent-shaped wear occurs.

Trading Co., Ltd. is a professional manufacturer and seller of flotation machine impeller covers. The main products are: polyurethane screens, polyurethane screens, rotor stators, polyurethane lined pipes, cyclones, conveyor cleaners, etc. Welcome to call us.