Polyurethane screen 80 mesh edge leakage

Writer: admin Time:2020-11-03 10:11 Browse:℃

Leakage from the 80 mesh edge of the polyurethane screen is a very serious problem. If the weight is light, the screened materials will be unqualified, and heavy materials may be screened again, which greatly affects economic efficiency and company reputation. It is usually not easy to find the problem of the edge leakage of the polyurethane screen, and it is too late now. The following aspects are for you to solve, the 80 mesh polyurethane screen has high screening efficiency. The interior of the polyurethane screen has self-cleaning performance, no clogging holes, and high screening efficiency. Due to the strong water permeability of polyurethane and the large cone angle (140 degrees) of the mesh, it can effectively prevent the adhesion of wet particles, so it is suitable for the screening and classification of wet particles. The polyurethane sieve plate of our factory adopts imported raw materials, and its elastomer and its own good relaxation properties effectively avoid the phenomenon of plugging under dynamic conditions.

Because the polyurethane elastic screen uses steel wire rope as the skeleton material, the polyurethane itself has a high elastic modulus, so it has high strength to absorb impact and high abrasion resistance, so it has high tensile strength, and its bearing capacity is rubber screen. More than 2.5 times. Its service life is 8-10 times that of ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. The production material of the polyurethane sieve plate belongs to the polymer organic elastomer, which has excellent wear resistance, bending resistance and large bearing capacity. The raw materials produced by polyurethane screens are specially treated to ensure that they will not delaminate under long-term alternating loads.

There are many reasons for the edge leakage of the polyurethane screen. First of all, the quality of the polyurethane screen is not up to standard, followed by the installation of the polyurethane screen, and the second is maintenance. Usually, these three situations are not mentioned.

1, the installation is not standardized

The installation of polyurethane screens can be said to be commonplace. The technicians of the production company and the screening company are not very concerned about the installation of the polyurethane screen. They feel that they have been installed for many years without repeating it. In fact, they have ignored the basic problem of instability of polyurethane screens over the years, and any product is constantly improving, sometimes only with subtle differences. The investigation found that the screening company had installed a polyurethane screen: when the old polyurethane screen was found to be unusable, please remove the fixing bolts on the surface of the screen first, then remove the tension plates on both sides of the screen frame, and then remove the screen. Use mechanical handles. The discarded polyurethane sieve was pulled out. They didn't know that the resistance caused many problems. This process seems very simple, it is easy to cause unevenness around the frame and cause damage. The correct way is to slow down and slow down during the drag-out phase. When you find the dragging process is very troublesome, please find out the reason for dragging it out.

When installing the polyurethane screen, the mesh surface of the polyurethane screen and the gems under the edge of the screen frame must be removed first. When paving, please pay attention to whether the surface of the sieve is flat and whether the edge of the sieve is tightly combined with the frame, and then tighten it. The plate is fixed with screen bolts.

2. Maintenance

After using for a period of time, any equipment and accessories must be repaired and overhauled, otherwise it will malfunction. The failure rate of the new polyurethane screen is usually very low, but when used for nearly 30 days, always check the screen to determine if there are any particles. If it is not flat, please check the tightness of the edge of the screen and the fixing plate in time. In the screening process, pay attention to regular inspections and listen to abnormal sounds, find problems in time, and make judgments in time. On the contrary, it was found that the polyurethane screen is difficult to handle leakage when it is damaged.

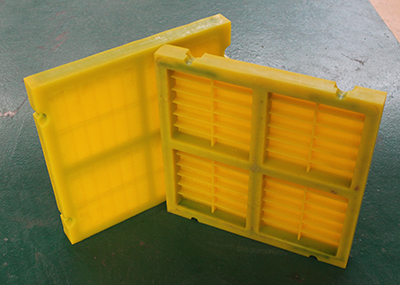

Polyurethane screen plate production process:

1. Synthesis of prepolymer

1. Raw materials, oligomer polyols: ODX2218, CMA21024; Polytetramethylene glycol (PTMG 1000), need to be dehydrated before use to make the moisture content less than 0.05%. Polyisocyanate: toluene diisocyanate (TDI2100).

2. Synthesis of prepolymer The dehydrated oligomer polyol is cooled to 40°C to 60°C, added to the reaction vessel, and a metered amount of toluene diisocyanate is added under constant stirring. After 30 minutes to 40 minutes, the reaction is slow. Heat to (80±)°C and continue to react for 2 to 3 hours. Sampling analysis-5NCO%, reaching 4.0% to 5.0%, defoaming for 30 minutes under a vacuum of 0.8kPa. Polyurethane screen

2, pouring process

1. Pretreatment of the metal frame In order to ensure the polyurethane screen has a certain rigidity during use, the screen is usually lined with a steel frame. The steel framework of small and medium-sized screen panels is mostly welded frame structure, and the tension screen uses multiple steel wires as the framework. In view of the complex working environment, the surface of the metal framework must be sandblasted to remove oil stains and rust spots on the surface, activate the surface and expand the bonding area. Polyurethane screen

2. Mold assembly After demolding the surface of the steel mold, place it in the skeleton, and the platform temperature rises to 110°C.

3. Casting chain extender of polyurethane sieve plate: dichloromethane, diaminodiphenylmethane (MO2 CA). Due to different production conditions, specific casting methods are divided into manual casting and mechanical casting.

Chaishang Trading Co., Ltd. has been focusing on the production and sales of polyurethane screens for more than 20 years. It is your good choice.