Methods to reduce the noise of curved sieve

Writer: admin Time:2020-10-20 11:12 Browse:℃

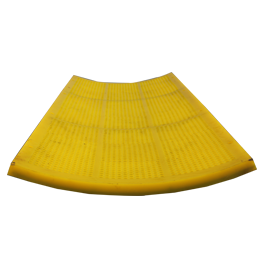

The characteristics of the curved screen are: the structure is simple, the screen frame is adjustable, and can be rotated 180 degrees to make it evenly worn, easy to maintain, durable, and high in screening efficiency. At present, the curved screen has been widely used in the coal washing industry in China and has been well received by users. The curved screen can be widely used for material screening in various industries. However, curved screens are a common source of noise. Generally, although the noise generated by curved screens is unavoidable during the production process, too much noise will have an adverse effect on the health of the staff, so what should we do to effectively reduce What about the noise of the curved screen? The following measures are proposed by the polyurethane screen manufacturer below, I hope it will be useful to everyone!

Introduction of curved screen

UHM curved screen The curved screen is advanced equipment produced by imported technology from the American company. It has been certified by the company and has reached the American quality standard. It is an arc-shaped fixed slotted screen, which can be divided into: ①Dense-medium arc-shaped screen: mainly used for dehydration, de-intermediation and desulfurization of coal washing system; In addition, they can also be used for the classification of other fine-grained materials.

Several methods to help you reduce the noise of the curved screen

1. Regularly check the looseness of the equipment parts of the arc screen. First of all, pay attention to whether the noise is caused by the looseness of the equipment parts. Therefore, to reduce the noise, you must first tighten all the parts on the arc screen, especially the screen that needs frequent replacement. Plate to avoid additional vibration due to loosening of individual components.

2. The curved screen uses polyurethane sieve instead of metal sieve. Because polyurethane material has small elastic modulus and large internal resistance, using polyurethane sieve instead of metal sieve can effectively reduce noise.

3. Arc-shaped sieve box side panels and constrained damping layers. The side panels and rear-end panels of the screen box are all made of thin plates by welding or riveting. These large-area thin plates will radiate more under the action of exciting force. For strong noise, the magnitude of the radiated noise of the panel is proportional to the square of the vibration speed of the panel. For this reason, constrained damping materials can be applied to the panel to achieve the purpose of noise reduction.

4. Apply damping treatment between the inner and outer shells of the curved screen bearing. Apply damping treatment between the inner and outer shells of the bearing. The rolling elements of the bearing can be made into hollow rolling elements or damping materials are added to the hollow rolling elements to effectively reduce the bearing Vibration and reduce bearing noise.

5. The curved screen is changed to a flexible web gear. In the vibration process, gear noise is also a noise source that is worthy of attention due to the gear's meshing and meshing. Synchronous gears used in general curved screens work in a strong vibration environment, and the impact is greater due to the greater impact and higher impact noise. Due to the large internal resistance and large elastic deformation of the rubber, it can not only reduce the impact of biting and biting, but also absorb more vibration energy, so flexible spoke gears can be used to achieve the purpose of noise reduction.

6. The curved screen is changed to a rubber spring. During the vibration process, relative sliding occurs between the spring end and the support. Because it is dry friction, the frequency of friction noise is high and the sound is loud, so that the local noise at the position of the curved screen spring is significantly increased. After the rubber spring is used, part of the noise can be significantly reduced.

7. Curved screen chute plus rubber liner, curved screen, straight line screen feed chute and discharge chute. The chute is welded with steel plate. The collision and friction of materials in the chute will also affect the noise of the curved screen. Putting rubber liners on the inner walls of the feeding and discharging chute can also reduce the noise of the chute.

The above is the relevant content brought by Chaishang Trading Co., Ltd. I hope it can be helpful to everyone.