Vibration dewatering screen repair

Writer: admin Time:2020-11-05 10:02 Browse:℃

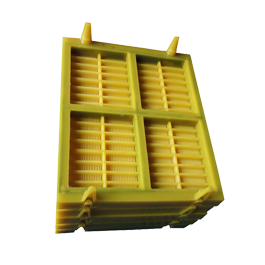

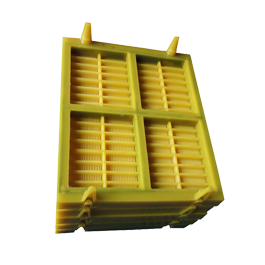

The screen of the dewatering screen is made of high-quality polyurethane material. Compared with the previous steel wire, the iron wire screen has its special advantages and has a longer service life. Under normal circumstances, the service life of the polyurethane screen is rarely one year. , It will not be broken within one year, but when the life of the polyurethane screen expires, how to replace the screen in the dewatering screen? What should be paid attention to during the replacement process? The screen has always been the most easily consumed part of the vibrating screen. When the vibrating screen equipment is used for a period of time, the screen will be damaged. The screen needs to be replaced. The life cycle of the screen plate of the dewatering vibrating screen is generally about one year. How to replace the new screen after the expiration of the screen? Let's learn together with the polyurethane screen manufacturer:

1. After the screen frame of the dewatering vibrating screen is installed in the screen box as required, it is necessary to load an extra 70mm screen into the corresponding outlet to avoid confusion again.

2. When cutting, the width of the Longzhong dewatering screen must be the same as the mesh frame, and the length of the screen must be 50~70mm longer than the dewatering screen frame;

3. When installing the high-frequency dehydration vibrating screen, it must be tightened, because the tension of the high-frequency screen is an important factor affecting the screening efficiency of the dehydration screen;

4. When installing a clear net bouncing ball, you must pay attention to the difficulty of screening the material and the number of meshes, and you cannot install it blindly;

5. If the specific gravity of the material is large or the number of screen meshes required to be installed for the dewatering screen is high, a suitable supporting mesh should be added under the screen. The purpose is to support and reduce the pressure of the material on the screen. To extend its service life;

6. When installing the pressure plate of the dewatering vibrating screen, be sure to pay attention to its flatness, and line it with a sponge sealing tape with strong elasticity to evenly lock, because this is the key to preventing mixing and affecting the service life of the vibrating screen. Important factors;

7. After installation, you should first use a little material to test the screen cloth and screening conditions. If the materials are transported uniformly, and the classification is accurate, there is no mixing phenomenon, then it can be put into use; on the contrary, if there is deviation or deviation For unevenness such as accumulation, adjust the flatness and uniformity of the screen surface of the dewatering screen or adjust the angle of the eccentric hammer of the vibrating motor; if there is a mixing phenomenon, check the seal of the dewatering vibrating screen and whether it is compressed.

In addition to the requirements for the screen, the dewatering screen also has requirements for the selection of the grid. There are generally two types of grids. One is the steel grid. The steel grid is not easy to damage, but it is more troublesome to replace the screen. . The other is a wooden net frame, but contrary to the steel net frame, the wooden net frame has a shorter service life, but it is more convenient to replace the screen. So what should be paid attention to when replacing the screen?

1. After the mesh frame of the dewatering screen is installed, when cutting the screen, an extra 50-70mm should be cut at the outlet of the dewatering screen to prevent the material on the screen from leaking at the outlet.

2. When cutting the screen, the width of the screen should be the same as the net frame.

3. When installing the screen, it must be tightened before installation to avoid shortening the service life of the screen due to large local forces during use.

4. If the processing volume is large, a suitable mesh support net should be added under the screen to support the purpose and extend the service life of the screen.

5. After installation, test the screen. Add a little material on the screen surface and start the dewatering screen. If the material is thrown forward evenly and the screening is sufficient, it can be used.

Reasons for the rapid damage of the screen of the high-frequency dewatering screen crusher:

1. The screen quality is unqualified. The screen generally has an upper screen layer and a lower stress layer, and the two layers are required to be closely attached. If the screen technology is poor, when the stress layer at the bottom of the screen is tightened, the screen layer is not tightened , The throwing force of drill cuttings is greatly reduced when working, and the drill cuttings cannot be discharged.

2. The screen is not tight enough, which causes the screen to vibrate, usually along the edge of the screen or at the edge of the rim to break or damage.

3. The steering error of the vibration motor. When debugging the steering of the vibration motor, based on the previous experience of using single-axis vibrating screens or linear vibrating screens, on-site operators think that as long as the drill cuttings move forward, this method is not suitable for translational elliptical vibration screen. If the motor rotates to the inside by mistake, the ejection angle is also forward 45°, but the drill cuttings have a backward rolling force. At this time, the forward movement speed of the drill cuttings will be much slower, and it will stay on the screen for a long time. As a result, drill cuttings cannot be discharged.

4. In many cases, customers and friends encounter various problems and need long-term work for the vibrating screen. It may be used for too long, and the vibrating screen has been working continuously for a long time, and making the vibrating screen "non-stop" is also a key cause of rapid damage.

5. No maintenance. Although the damage sometimes has a lot to do with quality problems, if the vibrating screen you buy back is not maintained, the rate of damage will also be accelerated.

The solution to the rapid damage of the high frequency dewatering screen:

1. Use sprayed water to flush the screen and drill cuttings to reduce the viscosity of the drill cuttings, but this method is only suitable for occasions where water is allowed;

2. Adjust the angle of the screen at the end of the sand discharge port downward, which is conducive to the discharge of cuttings by gravity, but it may cause slurry to run;

3. Improve the quality of the screen produced by the vibrating screen casting plant;

4. Change the mesh of the screen or adjust the flow rate of a single screen to ensure that the flow stop point of the drilling fluid is close to the outlet of the screen, so that the drilling cuttings can be smoothly discharged under the lubrication of the drilling fluid.

The above are the matters that should be paid attention to when replacing the dewatering shaker screen introduced by Chaishang Trading Co., Ltd. In addition to the requirements for the screen, the dewatering vibrating screen may also have a choice for the grid. There are wooden grids and steel grids for the grids. The two types of grids have their own advantages: wooden grids. It is easier to replace the screen, but it is easy to damage; the steel grid is not easy to damage, but it is more troublesome to replace the screen. Therefore, it is recommended to use a wooden grid.